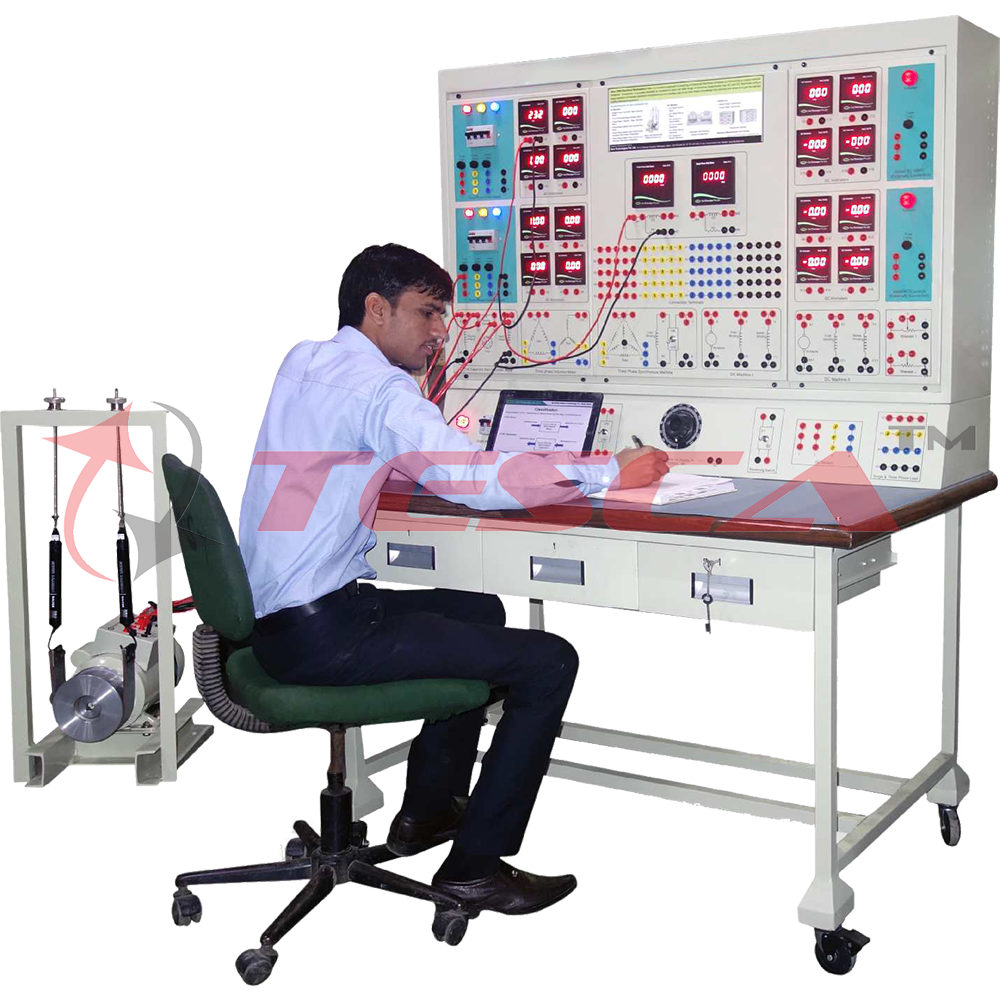

-Electrical Workstation

Order Code: 46969

Category: Electrical Machine Lab

46969 Electrical Workstation offers an excellent approach to the teaching of Elec t r i cal Machines pr inc iples by introducing a unique modular designed control unit. It provides flexibility for the students to carry out experiments over AC and DC ...

SPECIFICATION

46969 Electrical Workstation offers an excellent approach to the teaching of Elec t r i cal Machines pr inc iples by introducing a unique modular designed control unit. It provides flexibility for the students to carry out experiments over AC and DC Machines using a large selection of Industry standard inbuilt components. Electrical Machines is one of the most important area of study as it helps users to understand the operational characteristics and working of AC and DC Machines. 46969 enables user to put their theory knowledge into practice with ease. There is an additional facility to make wireless connection on workstation with computer and to monitor real time electrical parameters using computer interfacing software. Users can also observe a real time graph between any of the AC and DC electrical parameters on computer.

Workstation comprises of separate AC and DC measuring sections equipped with all the necessary instruments such as digital meters, facility to connect AC and DC Supplies along with protection devices such as Fuses, MCB’s, Supply Indicators, etc. There are multiple buses provided on the Workstation to make external connections while performing AC and DC Machines Experiments.

The design of the control unit ensures to get the highest quality practical experience to user. All the necessary protective measures are taken to avoid fault or danger.

Note: All AC & DC Machines along with supporting accessories are available optionally

Features

- Compatible for Machines upto 3HP

- Equipped with Measurement Facilities for Experimentation on AC Machines, DC Machines and Transformers

- Separate AC and DC Measuring Sections

- Diagrammatic representation of AC and DC Machines for better understanding

- Rust Free Powder Coating Paint

- Standard BS-10 terminals, patch cords for safety purpose

- Terminals provided to obtain Three Phase Fixed as well as Variable AC and DC Supplies with suitable protection

- High Quality Digital Tachometer for RPM Measurement

- Motors provided with standard Mechanical Loading Arrangement Facility

- Motors with “aluminum” casted Brake-Drum/Pulley with heat suppression facility

- Machines with Class “B” Insulation

- Flexible shaft coupling arrangement (Lovejoy) for Motor Generator (MG) Sets

- Machines provided with Heavy Duty Base/Channel with suitable interconnection

- Machines provided with suitable protections such as MCB's, Fuses, Motor Generator (MG) Sets provided with coupling protective cover

- Generator with Electrical Loading Arrangement Facility

- Durable good quality spring balance

- Designed by considering all the safety measures

Technical Specifications

Electrical Measuring Instruments

AC Ammeter (4 Nos.)

- Type : Digital

- Range : 10A

AC Voltmeter (4 Nos.)

- Type : Digital

- Range : 450Vrms

DC Ammeter (4 Nos.)

- Type : Digital

- Range : 20A

DC Voltmeter (4 Nos.)

- Type : Digital

- Range : 300V

Single Phase Wattmeter (2 Nos.)

- Type : Digital

- Range : 4kW

DC Supply (for excitation purpose only)

- Voltage : 300V ± 10%

- Current : 2Amp

DC Power Supply

- DC Output Voltage (Fixed) : 220V ± 10%, 2A

- DC Output Voltage (Variable) : 220V ± 10%, 25A

Protective Devices

- Three Phase MCB (TPN) : 2 Nos.

- Interconnections : 4mm BS-10 Safety Terminals

Object

DC Shunt Wound Motor

- Study of Operational Working and Principle of DC Shunt Motor

- Study of running and reversing phenomenon of DC Shunt Motor

- Study of No Load Characteristic of DC Shunt Motor

- Study of Load Characteristic of DC Shunt Motor

- Study of speed control of DC Shunt Motor using armature voltage control and flux field control method

DC Series Wound Motor

- Study of Operational Working and Principle of DC Series Motor

- Study of running and reversing phenomenon of DC Series Motor

- Study of Load Characteristic of DC Series Motor

- Study of speed control of DC Series Motor using armature voltage control and flux field control methods

DC Compound Wound Motor

- Study of Operational Working and Principle of DC Compound Motor

- Study of running and reversing phenomenon of DC Compound Motor

- Study of Load Characteristic of DC Cumulative-Compound Wound Motor

- Study of Load Characteristic of DC Differential-Compound Wound Motor

DC Shunt Wound Generator

- Study of Operational Working and Principle of DC Shunt Generator

- Study and measurement of Open Circuit Characteristic of DC Shunt Generator

- Study and measurement of External Characteristic of DC Shunt Generator

- Study and measurement of Internal Characteristic of DC Shunt Generator

DC Series Wound Generator

- Study of Operational Working and Principle of DC Series Wound Generator

- Study and measurement of Open Circuit Characteristic of DC Series Generator

- Study and measurement of Load Characteristic of DC Series Generator

- Study and verify the Field Test of DC Series Machine and correspondingly determine the efficiency of DC Series Motor and Generator at any desire load

DC Compound Wound Generator

- Study of Operational Working and Principle of DC Compound Wound Generator

- Study and verify the Load Characteristics of Long Shunt Cumulatively Compound Generator

- Study and verify the Load Characteristics of Short Shunt Cumulatively Compound Generator

- Study and verify the Load Characteristics of Long Shunt Differentially Compound Generator

91-9829132777

91-9829132777