Boiler Simulator With DAQ

Order Code: 32453

Category: Boiler & Steam Generators

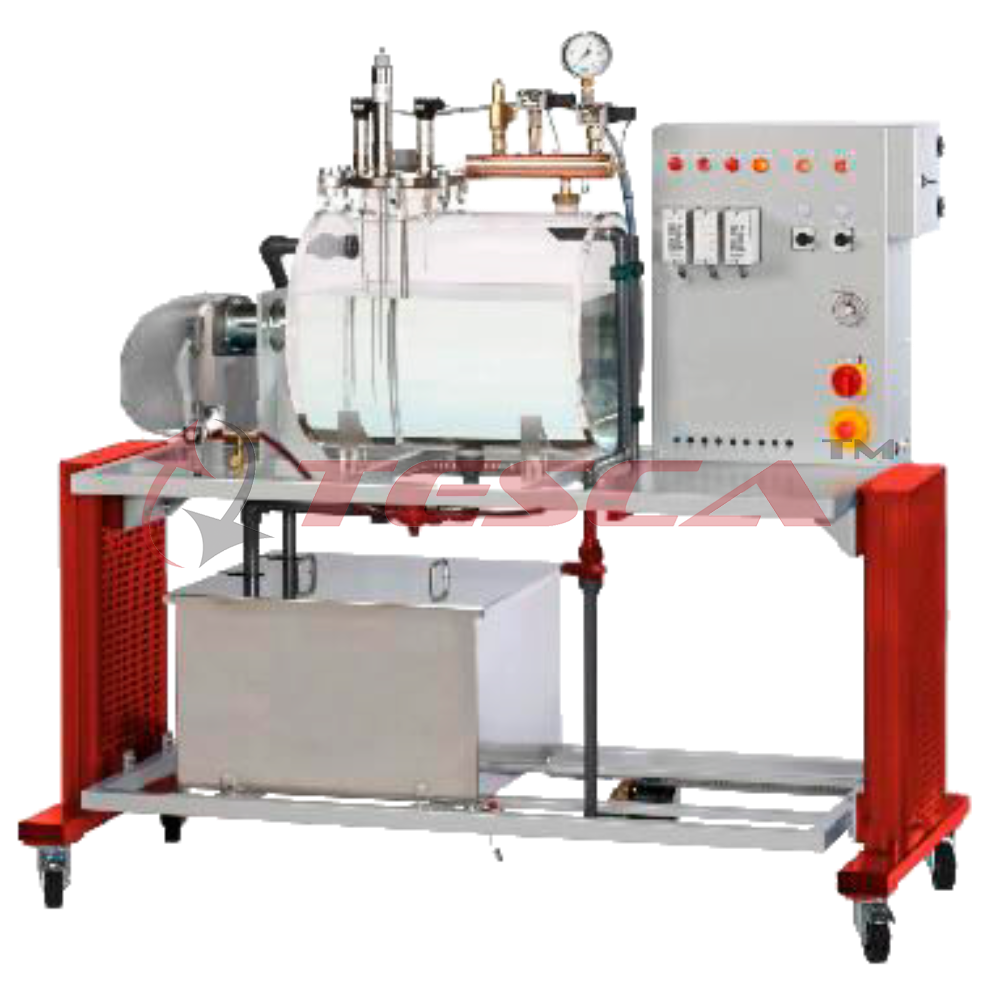

Tesca Utility Boiler 32453 is a typical drum-type boiler widely used in the oil refinery and petrochemical plants for steam generation. Tesca Bench Top Utility Boiler Simulator Model 32453 is designed to demonstrate the thermodynamic basic principa...

SPECIFICATION

Tesca Utility Boiler 32453 is a typical drum-type boiler widely used in the oil refinery and petrochemical plants for steam generation.

Tesca Bench Top Utility Boiler Simulator Model 32453 is designed to demonstrate the

thermodynamic basic principal of boiling phenomenon.

32453 enables user to study the fundamental pressure- temperature relationship of saturated steam in equilibrium with water.

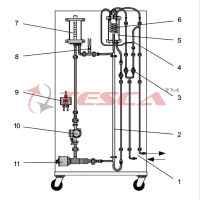

The Boiler consists of a stainless steel pressure vessel fitted with a high pressure immersion electrical heater.

It comes with a safety valve, temperature sensor and Bourdon type pressure gauge. Water inlet valve and discharge valve are also installed.

32453 comes with transducers for temperature and pressure for students to enable to take readings for respective values on a digital indicator.

Heater power supply is controlled through control panel. The heater is protected from burn-out by setting the maximum operating temperature on the temperature controller.

Optionally Data Acquisition System can be offered for Data Logging; Signal Analysis; Process Control; Real-time Display; Tabulated Results & Graph of Experimental Results Utility Boiler Module consists of Simulator and Tutorial.

The highlights of Utility Boiler Simulator

- Permits practice:

- Start up

- Shutdown

- Normal operations

- Troubleshooting

- Simulation of drum shrink-and-swell phenomena

- Burner flame out and unstable flame conditions

- Detailed radiation and convection section heat transfer

- Variable fuel characteristics and heating values

- Stoichiometric combustion model

- Effect of atomizing steam

- Typical advanced boiler control system

- Dynamic display of flame color and length

- Plant alert and monitor:

- Abnormal ignition

- Black smoke in stack

- Explosive situation

Utility Boiler Tutorial Topics

- Application of boiler

- Types of boiler

- Boiler components:

- Deaerator and feedwater system

- Drum, water circulation and heating system

- Superheater and heat recovery system

- Combustion system

- Draft system

- Steam distribution system

- Boiler performance:

- Burner characteristics

- Combustion air

- Damper and air registers

- Fuel characteristics

- Boiler control system:

- Three elements level control

- Steam temperature control

- Steam pressure control

- Fuel control

- Total calorie(BTU) control

- Combustion air control

- Oxygen control

- Cross limit control

- Normal operation

- Start-up and shutdown operations

- Purge, trips and interlocks

- Troubleshooting:

- Combustion condition

- Leakage

- Soot

- Instrument errors

Specification

- Pressure Vessel

- Capacity: 5 – 50 liters

- Material: Stainless steel (304 or 316)

- Pressure Gauge

- Type: Bourdon type

- Range: min. 0 to max. 20 bar

- Temperature Sensor

- Range: min. 0 to max. 200 ?C

- Transducers

- Temperature and pressure

- Operating Pressure

- Max. 15 bar

- Electrical Heater

- Power: 2 kW

- Type: Immersion type

- Temperature Controller

- Thermocouple/PT100 input

- Safety: Temperature controller: pressure relief valve

Optional, Data Acquisition System DAQ

- Electronic signal conditioning system Windows based software:

- Data Logging

- Signal Analysis

- Process Control

- Real-time Display

- Tabulated Results

- Graph of Experimental Results

Requirements

- Mains Power Supply 220 – 240V AC, 50Hz, 1Ph

- Cold Water Supply

- Approved Safety secured laboratory suitable to house Boilers under pressure

91-9829132777

91-9829132777