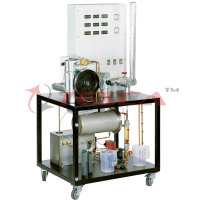

Compact Steam Power Plant (Includes DAQ, Super Heater, Blow Down Tank)

Order Code: 32451

Category: Boiler & Steam Generators

Study of power generation using steam boiler and performance of steam generator is focus of this trainer. Tesca has designed this system in such fashion that enables students to investigate all the parameters governing the utilization & maintenanc

SPECIFICATION

Description

Study of power generation using steam boiler and performance of steam generator is focus of this trainer. Tesca has designed this system in such fashion that enables students to investigate all the parameters governing the utilization & maintenance of a typical power plant. The system uses a small sized boiler unit that runs on LDO/gas. The generated steam is then used to run the steam turbine with in turn runs the A.C. Generator to produce the electricity or loading can be done by using Alternator & Bulb bank. A loading arrangement is also given for load test. The unit is fitted with a colored mimic diagram that illustrates the constructional and operational features. The various aspects of boiler and turbine operation and maintenance can be studied. Instrumentation is provided to measure Temperatures and Pressures. Temperature pressure characteristics of boiler can also be plotted.

Features

- Laboratory-sized specially designed Steam Power Plant

- Process control system based on PLC

- Plant monitored and controlled via optional touchscreen control station

studied. Instrumentation is provided to measure Temperatures and Pressures. Temperature

pressure characteristics of boiler can also be plotted.

System Components

- Boiler 200 kg/Hr at 11bar

- Single-stage Steam turbine with Curtis wheel and hydraulic speed regulator: 1.5 KW @ 3000RPM

Fuel consumption: 12L/h

Heat-up time: 8min

Max. pressure: 13bar

Heater: power 7kW

- Condenser shell & tube type.

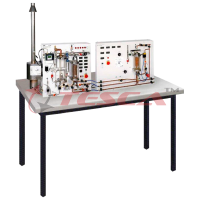

- Pressure measurements: 3 x 0 to 16 bar, 2 x 0 to 4 bar, 1 x -1 to 1 bar

- Chimney

- Orifice meter

- Control valve: Electric Solenoid type

- Pump Centrifugal pump: 2Hp capacity & reciprocating pump.

- Flow meter: Flow rate 0 to 160L/min (cooling)

- Water Software

- Steam Calorimeter-spearating & throtting calorimeter

- Temperature inductor: 12 channel input K type thermocouple

- Fuel supply system: vloumetric type capacity 50Liter

- K type thermocouple temp. sensor - Temperature measurements: 12 x 500 to 4000C; 1 x 0 to 1000C

- Torque measurement: 0 to 10Nm

- Digital tachometer 0-9999rpm

- Voltmeter 0-500V

- Ammeter 0-10Amp.

- Loading Arrangement-Electrical Alternator

- Lamp bank

- Control Panel

- Cooling tower (Optional)

Optional Accessories

- Data Acquisition system with scanner

- Super heater

- Blow down tank

- Computer

Range of Experiments

- Study of steam operated power plant.

- First and second low of fthermodynamics analysis of completer steam plant.

- Determination of turbine power outpuit with closed nozzles.

- Measurement of power by dynamometer

- Study of Efficiency of generator

- Study of specific consumption of steam against power generator.

- Study of thermodynamic efficiency.

Service Required at Site

- Electric supply 3 phase 440V AC with neural & proper earthing

- Water supply for Boiler & drainage facility Cooling water 10m3/hr

- Sump water tank 15000ltr capacity approx. Compressed air connection: 4.5bar, 150ltr/hr

- Boiler feed water tank 1000ltr

- Piping for plant to site water tanks & drainage tank

- Diesel-40 liter

- Holes in wall for smoke sute & other drainage

- Foundation & Trench

- Room size: 8 x 5 x 7 mtr

Optional Accessories

computerized Data Acquisition System

91-9829132777

91-9829132777