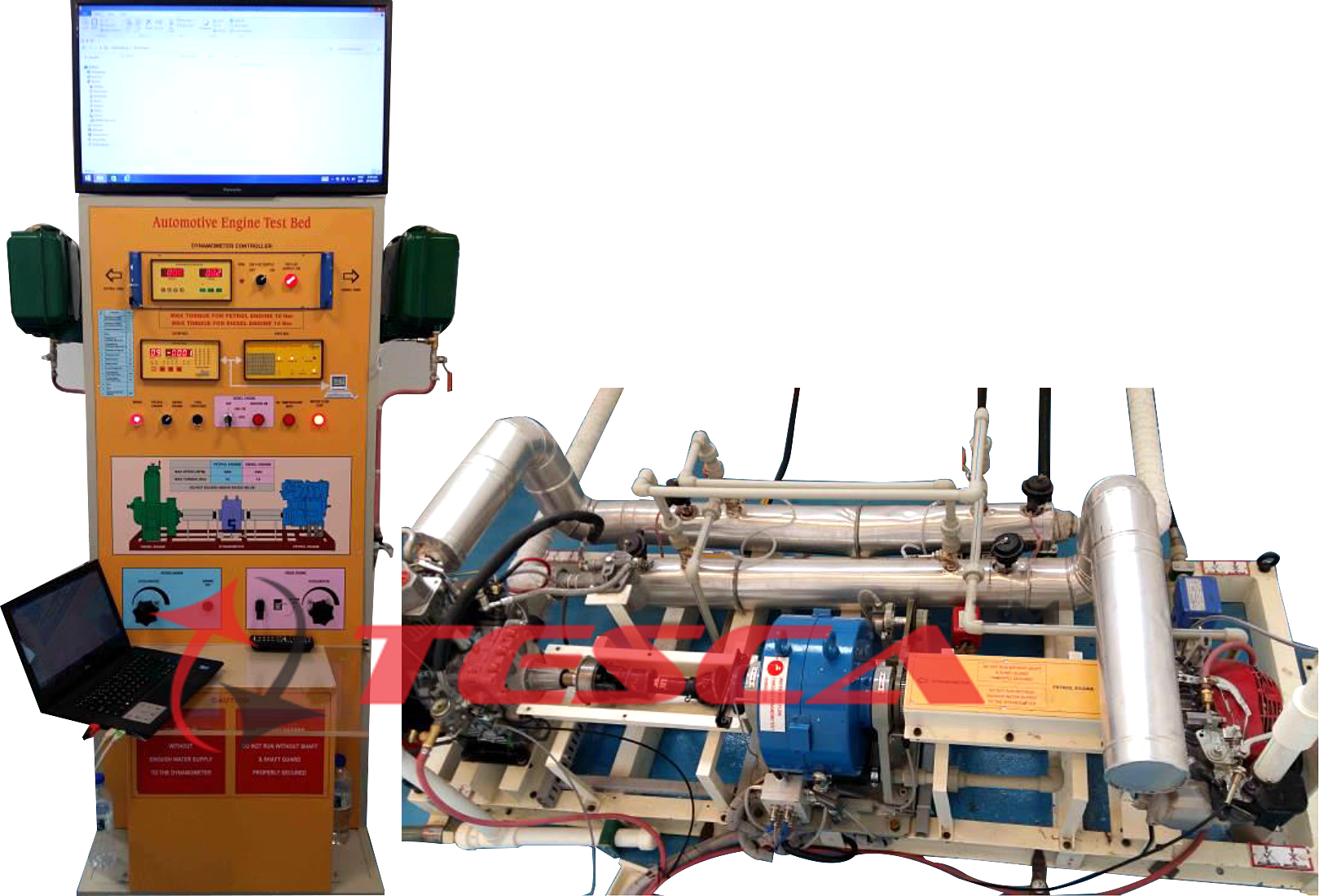

Computerized IC Engine Test Rigs: Three Cylinder Four Stroke MPFI Petrol Engine: 796 cc

Order Code: 32714

Category: Technology Trainers

System Features Basic Unit Compact, comprehensive, sturdy design Complete instrumentation for experimentation of I.C. Engine performance. Direct reading of parameters like fuel consumption, air flow, temperature and RPM e...

SPECIFICATION

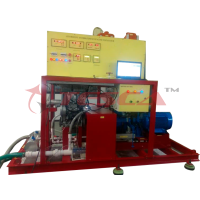

System Features Basic Unit

Compact, comprehensive, sturdy design

Complete instrumentation for experimentation of

I.C. Engine performance.

Direct reading of parameters like fuel consumption, air flow, temperature and RPM etc.

Demonstration of performance of I.C. Engine at different load.

Fault Trainer as optional attachments.

Computerization Unit

Data Acquisition with high performance, various function parameter IP & OP.

Low cost, Portable, compact comprehensive design

Complete instrumentation for reading different parameters & calculations of Engine Performance.

Very high -speed dynamic signal acquisition is possible.

Computerized Load or speed control attachment as optional accessories.

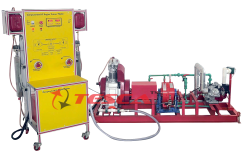

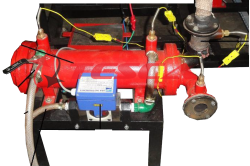

System Description Basic Unit

Study of performance of internal combustion engines

& its calculation is important feature of this trainer. System is having unique feature of calculating all efficiency of internal combustion engine including heat balance sheet. The Engine & Dynamometer is mounted on base structure. Sci-tech Engineers have design the system in such faction that easily operate; demonstrated & requisite experimentation can be performed. System has facility of measuring Engine brake load, speed, consumption of air, consumption of fuel, temperature at different locations, mass flow of water.

Computerization Unit

System is having unique feature of direct reading & automatic calculating all efficiency & heat balance sheet of internal combustion engine. The online graphical representation of important parameter is displayed on screen to see effect of change in load or speed. Final result & graph are in built available in software. System has facility of measuring Engine brake load, speed, consumption of air, consumption of fuel, temperature at different locations, mass flow of water.

P- q / P-V Arrangement Console

System is having unique feature of direct Engine Dynamic Pressure & Engine crank angle q or Engine Volume (V) can be measured & plot on computer screen. It gives on line representation of Engine Dynamic Pressure & Engine crank angle q to study effect of change in load & speed. For correct sensing of Pressure, piezo quartz type transducer from PCB USA or same quality is used.

Computer Controlled Unit

System is having unique feature of direct control of Engine load or speed from keyboard & mouse. This system is having automatic operation controller & actuator. This can control parameter on line of engine operation.

List of Experiments

Calculation of Mechanical Efficiency & Plot brake power versus mechanical efficiency.

Measurement & Calculation of Volumetric efficiency.

Measurement & calculation of specific fuel consumption

Measurement & calculation of brake thermal efficiency

Determining air / fuel ratios

Heat Balance Test

Brake Mean Effective Pressure and brake power on the basis of engine speed

Plotting of exhaust temperature versus Speed

Study of Engine Dynamic Pressure & Crank Angle . (If P - V Arrangement Console is optional ordered)

Calculation of Indicated Mean Effective Pressure. (If P - V Arrangement Console is optional ordered)

Computer controlled of parameter like load or Engine speed. (If Computer controlled Unit is optional ordered.)

Operation & Maintenance Manual

Self-explanatory operating & maintenance manual will be provided. This will include Theory, operating procedure, standard results, and maintenance procedures.

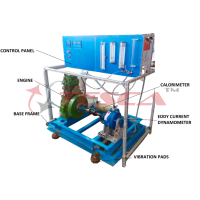

System Components Basic Unit

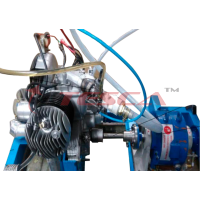

Engine: Multi-cylinder Petrol or Diesel Engine

Three Cylinder Four Stroke MPFI Petrol Engine: 796 cc, Max. Power 29 kW @5500 RPM

Dynamometer suitable for above mentioned Engine. (Choose any one from List motioned below)

Hydraulic Dynamometer (Capacity: Up to 37 kW @ 3000 RPM)

Eddy current Dynamometer (Capacity: 10 KW, 20KW, 30 KW, 80KW, 150KW)

Calorimeter- Shell & Tube type heat exchanger will be used. Water-cooled.

Air Box – MS powder coated / PVC air box with orifice meter will be used.

Fuel Tank: capacity 5 liters.

Base frame – Made up of mild steel C channel duly powder coated.

Control Panel - for mounting of all indicators.

Digital Temp. Indicator with temperature sensor – 6 channel 0-400°C (Optional)

Rotameter: 600 LPH for calorimeter water flow measurement.

Electrical switches, wiring & Piping

P- q, P- V Arrangement Console (Optional)

Engine cylinder pressure.

Piston position marker.

Optional Accessories

Multi Engine Mounting Test Bed.

Different type of Engines.

Computer Based Training Software.

Cut Section Models

Computer

Fault Trainer

Computerization by using Multi Function Recorder Unit with different digital signals & RS232 Output.

Cooling water flow transmitter

Service Required at Site

Electric Supply 230V 50Hz. With proper earthing.

Tap Water supply & drainage.

Water circulation at ambient temperature or cooling tower @ 100LPH

Exhaust chimney

Concrete foundation.

91-9829132777

91-9829132777