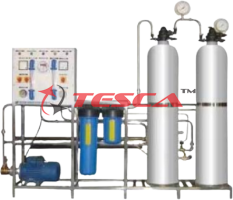

Liquid Liquid Extraction Unit

Order Code: 32299

Category: Thermodynamics Lab

Features Self-contained floor standing unit with integral control and instrumentation console Three-stage continuous extraction process, can also be configured as one or two stages Independent vessel for closed-loop batch extraction Temperature...

SPECIFICATION

Features

Self-contained floor standing unit with integral control and instrumentation console

Three-stage continuous extraction process, can also be configured as one or two stages

Independent vessel for closed-loop batch extraction

Temperature control at each stage

Individual control of solvent feed pumps at each stage, of cell rotation rate and of feed rate

Probes at each stage allow full monitoring of the process

With the data logger, the product concentrations can be directly displayed in real-time (for the recommended material)

Optional data logging accessory with USB interface and educational software

Tesca Pilot Plant for Liquid-Liquid Extraction Unit comprises a glass separation column, 1500mm long and 50mm diameter, packed with glass Raschig rings which provide a large surface area for the extraction process. Four process tanks are included, a feed tank and collection tank for the organic phase and a feed tank and collection tank for the aqueous phase.

The aqueous circuit includes a variable speed rotary diaphragm pump with built in rotation counter that allows the flow rate to be determined. Conductivity and temperature sensors in both the feed and return lines allow the amount of acid transferred to the aqueous phase to be determined.

The organic circuit uses a variable speed diaphragm pump that is air powered and contains no electrical components allowing safe operation using Kerosene. The Kerosene containing a trace of Acetic acid is pumped from the organic feed tank to the base of the extraction column. Demineralized water is pumped from the aqueous feed tank to the top of the extraction column. The density difference between the phases causes counter current flow in opposite directions through the packed column where the acid is removed from the organic component into the aqueous component. The two phases exiting the column are collected in the appropriate return tank. The phase boundary can be changed between the top of the column and the bottom of the column by operating a single valve. Fine adjustments can be made to the location of the lower boundary to compensate for variation in specific gravity of the organic phase.

Temperature and conductivity sensors allow the concentration of acetic acid in the aqueous phase to be determined at the inlet and outlet of the column. From this information the extraction efficiency of the process can be calculated. All the sensor readings and calculated values are available for (optional) data logging on a personal computer (not supplied).

To obtain accurate results it is important that pure

water is used for the input. The Tesca Pilot Plant for Liquid-Liquid Extraction Unit includes a float- operated level control valve allowing continuous topping up using a pumped supply of demineralized or deionized water, if available.

After use, the organic phase will retain a small amount of acid. If required, the concentration of acid can be established using titration, and then topped up with more acid ready for the next run at the required concentration.

Using the recommended Kerosene system, this process can be repeated indefinitely.

Alternatively, the used Kerosene can be disposed of periodically and replaced. As Kerosene is inexpensive and readily available this causes no problems and a solvent recovery system is not required.

Note: Tesca Pilot Plant for Liquid-Liquid Extraction Unit has been specifically designed for use with Kerosene. Although Kerosene is classed as flammable, it is difficult to ignite and is safe to use providing reasonable handling precautions are taken. A number of design features have been incorporated into the equipment to ensure safe operation. For safe operation, 32299 can only be operated at an ambient temperature less than 35ºC. Hence the equipment should be installed in a temperature controlled laboratory if this temperature will be exceeded.

Detailed Operation & Maintenance Manual is provided along with the trainer.

Specifications

Wheeled 30x30mm extruded aluminium sectioned frame structure

Glass extraction column with diameter of 40-50 mm, h=600-1500 including disc agitator with speed electronic indicator

Borosilicate glass top and bottom separators

2 metering pumps: feed pump with max flow rate of 1000 mL/min and solvent pump with max flow rate of 1200 mL/min

Plastic feeding tank for the light phase, capacity of 30 L approx

Plastic feeding tank for the heavy phase, capacity of 15-30 L approx

Plastic tank for the extracted product, capacity of 30 L approx

Plastic feeding tank for the refined product, capacity of 30 L approx

Switchboard IP55 with plant synoptic and ELCB and emergency pushbutton.

Complete and exhaustive manual, English language.

Experiment Capabilities

Separation of two components liquid mixture by extraction using a solvent

Determination of the extraction efficiency

Mass balance

Calculation of the number of theoretical stages

Number of transfer units and height of a transfer unit

Determination of Distribution Coefficient: The objective of this experiment is to determine the distribution coefficient for the system organic solvent-Propionic Acid-Water and to show its dependence on concentration. The solvent (water) and solution (organic solvent/propionic acid) are mixed together and then allowed to separate into the extract phase and the raffinate phase. The extract phase will be water and propionic acid and the raffinate, organic solvent with a trace of propionic acid. The distribution coefficient, K, is defined as the ratio.It is assumed that equilibrium exists between the two phases. At low concentrations, the distribution coefficient is dependent on the concentration and thus Y = KX.

Basic Operation of the Liquid/Liquid Extraction Column: The objective of this experiment is to observe the hydraulics of counter current flow in a packed column.The experiment will be carried out using the two immiscible liquids organic solvent and water and the column will be operated in the two modes: (a) The aqueous phase as the continuous medium. (b) The organic phase as the continuous medium.

Overall Mass Balance and Mass Transfer Coefficients with the Aqueous Phase as the Continuous Medium: The objective of this experiment is to demonstrate how a mass balance is performed on the extraction column, and to measure the mass transfer coefficient with the aqueous phase as the continuous medium.

Overall Mass Balance and Mass Transfer with the Organic Phase as the Continuous Medium: The objective of this experiment is to demonstrate how a mass balance is performed on the extraction column, and to measure the mass transfer coefficient with the organic phase as the continuous medium.

Demonstration of Solvent Recovery: The objective of this experiment is to recover the solvent used in the liquid/liquid extraction experiments using the distillation column

Services Required

Electric Supply 230 V AC, Single Phase, Earthed.

91-9829132777

91-9829132777