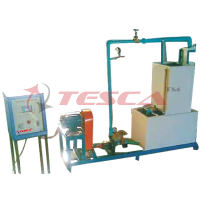

Mixing Process By Stirring

Order Code: 32113

Category: Fluid Mechanics Lab

Features: Visualization of flow fields when using various stirrer types High-performance stirring machine with speed control Determination of mixing time of solutions Mixing of emulsions and suspensions Influence of mixin...

SPECIFICATION

Features:

Visualization of flow fields when using various stirrer types

High-performance stirring machine with speed control

Determination of mixing time of solutions

Mixing of emulsions and suspensions

Influence of mixing processes on heat transfer

Power demand during stirring

During stirring, the continuous phase is liquid. With Tesca Mixing Process by Stirring the production of solutions (solid dissolved in liquid), emulsions (a mixture of immiscible liquids), and suspensions (insoluble solid in liquid) can be investigated.

Mixing takes place in a tank that is resistant to chemicals and heat-resistant. With the high- performance stirring machine, even high-viscosity mixtures can be produced. The speed is adjustable. The torque is indicated on the unit’s digital display. This enables the power demand to be determined. Nine different, easily interchangeable stirrers are provided. With plastic balls which are dispersed in the water, it is possible to observe the characteristic flow fields of the different stirrer types. Flow impeders can be inserted in the tank to investigate their influence on the mixing process. To determine the mixing time and mix quality of solutions, a conductivity meter is available. The device can also be used to measure temperatures.

A removable coiled tube serves as a heat transfer medium. It can be used for heating or cooling with water from the laboratory supply. A valve with a precise adjustment is used to adjust the flow rate. This enables the influence of mixing processes on heat transfer to be investigated.

Specifications:

1. Investigation of mixing processes during stirring

2. Transparent stirred tank with 4 removable flow impeders

3. Speed-controlled stirring machine with a digital torque indicator

4. 9 interchangeable stirrers: axial-, radial-, tangential-conveying

5. Removable coiled tube for cooling or heating with external water supply

6. Portable device for measuring conductivity and temperature

Technical Specifications:

Stirred tank

Capacity: approx. 20L

Material: DURAN glass and PVDF (base) Stirring machine

Speed: 50…2000min-1

Max. power output on the shaft: 100W Stirrers

5 propeller stirring heads

s 2x 3 blades, D=70mm / 100mm

s 1x 4 blades, D=70mm

s 2x 2 blades (angled), D=70mm / 100mm

3 paddle stirring heads

s 2x paddle: 70x70mm with 3 / 6 holes

s 1x paddle: 70x100mm with 10 holes Ÿ 1 turbine stirrer with shaft: D=50mm Coiled tube

Diameter: approx. 140mm Ÿ Material: stainless steel Measuring ranges

Conductivity: 0…200mS/cm

Temperature: 0…85°C

Speed: 50…2000min-1

Experiments:

Flow fields of various stirrer types

Power demand, mixing time, mix quality dependent on

Stirrer type

Speed

Materials used (density, viscosity)

Insertion of flow impeders

Observation of the suspension state of suspended solids when using different stirrers and at different speeds

Observation of the droplet size of emulsions when using different stirrers and at different speeds

Influence of mixing processes on heat transfer

Requirements:

Mains Power 220 – 240V @ 50Hz, 1Ph

91-9829132777

91-9829132777