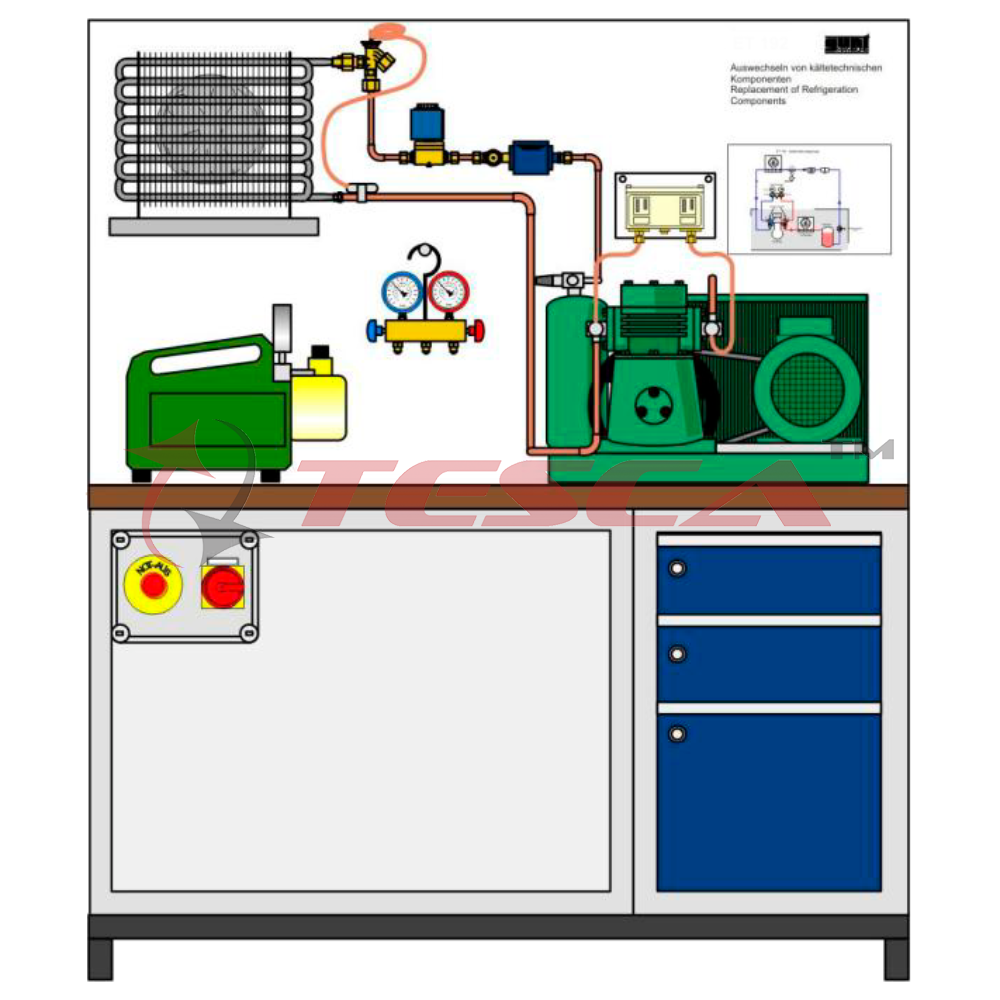

Refrigeration Repairs/Replacement Components

Order Code: 32430

Category: Refrigeration & Air Conditioning Lab

The replacement of a faulty compressor or other components of the refrigeration system are amongst the repeated activities of a mechatronics engineer for refrigeration. Tesca Refrigeration Repair/Replacement Component 32430 allows for training in the

SPECIFICATION

Features

- Practical service tasks in refrigeration systems1

- Replace typical components of a refrigeration system: compressor, pressure switch, filter/drier, solenoid valve and expansion valve1

- Siphoning off, displacing refrigerant, replacement, evacuation, filling and adjustment

The replacement of a faulty compressor or other components of the refrigeration system are amongst the repeated activities of a mechatronics engineer for refrigeration. Tesca Refrigeration Repair/Replacement Component 32430 allows for training in these processes. The consequences of incorrect procedures can be demonstrated.

The components are integrated into an operational refrigeration system. This allows for the practical testing of the functionality of individual components after replacement. The following activities must be carried out e.g. after replacing a compressor:

- Refrigerant displacement (pump-down) into the condenser/receiver (should this not be possible: siphoning off the refrigerant)

- Disconnection of the compressor at the service valves

- Disconnection of electrical connections

- Compressor replacement, correcting oil level, if necessary

- Reconnecting electrical connections

- Reconnecting the compressor with the service valves

- Evacuating the compressor and making the connection to the system

- Compressor test run, checking for leaks and replenish refrigerant, if necessary

- Checking the system pressures

- To carry out the service tasks, the tool set and the filling and evacuation equipment are required.

- The well-structured instructional material sets out the fundamentals and provides a step-by-step guide through the exercises.

Specifications

- Trainer from the practical series for the training of mechatronics engineers for refrigeration

- Service exercises in refrigeration systems

- Complete refrigeration circuit with open compressor, air-cooled condenser, receiver and air cooling evaporator

- Replaceable components: compressor, filter/drier, pressure switch and solenoid valve

- Recommended accessories evacuation equipment and tool set

- Overall arrangement on robust workbench

- Refrigerant R134a, CFC-free

Technical Specifications

Open refrigerant compressor

- Drive power: 0,75kW

- Refrigeration capacity: 1245W at -5°C/36°C

- Maximum system pressure: 18bar

Pressure switch

- LP: -0.2...7bar

- HP: 10...32bar

Experiments

- Familiarization with and carry out basic activities for the servicing of refrigeration systems

- Replacement of

- Compressor

- Pressure switch

- Filter/drier

- Solenoid valve

- Expansion valve

- Refrigerant displacement (pump-down)

- Mechanical and electrical assembly and disassembly of components

- Replenish refrigerant and compressor oil

- Leak test

- Compressor test run

- Adjustment of expansion valve and pressure switch

Requirements

230V, 50Hz, 1 phase or 120V, 60Hz, 1 phase

91-9829132777

91-9829132777