CNC Turning Center with X y z - axis

Order Code: 54014

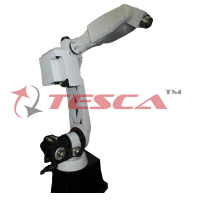

Category: Mechatronics/ Robotics/ CNC Lab

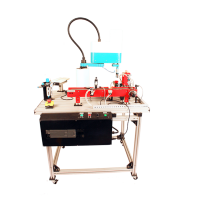

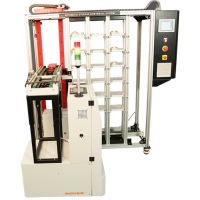

54014 a 3 Axes CNC Vertical Machining Centre with FANUC, Siemens Control and with option of 8 Station Automatic Tool Changer. 54014 is a smart CNC vertical milling machine designed specifically for industrial specifications. It is a precision...

SPECIFICATION

54014 a 3 Axes CNC Vertical Machining Centre with FANUC, Siemens Control and with option of 8 Station Automatic Tool Changer.

- 54014 is a smart CNC vertical milling machine designed specifically for industrial specifications.

- It is a precision milling machine totally enclosed high visibility sliding guard.

- It uses industrial controls such as FANUC / SIEMENS

- The machine is provided with widely placed precision LM guide ways for increased rigidity and high accuracy.

- The machine is equipped with cartridge type spindle power with 8 station carousel type ATC , integrated base with coolant tank.

Objective

Interpret the components, concept of intermittent level industrial machine and learn about the advanced Fanuc/Siemens controller handling & programming skills for a milling machine to produce different kinds of components with optimized cycles and execute different kinds of practical applications simulated as exercises.

Learning Objectives:

Having successfully completed this lab, the student will demonstrate knowledge in –

- Learn about techniques to optimize the cutting parameters

- Advanced programming techniques matching industrial standards.

- Advanced machining cycles & control techniques.

- Knowledge on centralized Lubrication and re-circulating coolant system

- Learn about Intricate Tool changers system.

- Maintenance of CNC machineries and Trouble shooting

|

|

SPECIFICATIONS |

||

|

|

Travel |

||

|

|

X axis |

mm |

300 |

|

|

y axis |

mm |

250 |

|

|

Z axis |

mm |

250 |

|

|

Table |

||

|

|

Table size |

mm |

500 x 250 |

|

|

T- Slot |

mm |

3 x 14 x 80 |

|

|

Load on table |

Kgs |

80 |

|

|

Spindle |

||

|

|

Spindle |

|

Direct coupled, Cartridge Type |

|

|

Spindle nose to table top |

mm |

105-355 |

|

|

Spindle to Column |

mm |

290 |

|

|

Spindle nose taper |

|

BT 30 |

|

|

Spindle Motor Power S1 (15 minute rating in parenthesis) |

Kw |

3.7 (5.5) |

|

|

Programmable spindle speed |

rpm |

100-6000 |

|

|

CNC detail |

||

|

|

Control system |

|

FANUC 0i MF / SIEMENS 828D |

|

|

Positioning accuracy |

mm |

0.01 |

|

|

Repeatability |

mm |

±0.005 |

|

|

Axis motor |

|

AC Servo motor |

|

|

Programmable feed rate |

mm/min |

0 - 10000 |

|

|

Rapid motion speed and feed rate X, Y, Z |

m/min |

15/15/10 |

|

|

Guideways |

mm |

P Grade Ball type LM guideways Size 20/20/25 |

|

|

Ball screws X/Y/Z |

mm |

C3 Class Dia 25 x 10 |

|

Power source |

|||

|

Main supply |

|

415V, 3 Ph., 50/60 Hz, 12 KVA, 32A |

|

|

Coolant / Lubrication |

|||

|

Coolant Capacity |

ltrs |

80 |

|

|

Pump Output |

Lpm |

40 |

|

|

Coolant motor |

Kw |

0.1 |

|

|

Lubrication |

|

Automatic lubrication system |

|

|

Machine dimensions |

|||

|

Machine Dimensions L x W x H (approx) |

mm |

1550 x 2180 x 2150 |

|

|

Weight (approx.) |

Kgs |

1400 |

|

|

Features |

|||

|

Compatibility / Upgradable |

|

FMS / CIM system |

|

91-9829132777

91-9829132777