PLC Trainer Kit With 10 Industrial application

Order Code: 54026

Category: Mechatronics/ Robotics/ CNC Lab

Objective Understand & discern the functionality of PLC, interfaces of various devices and components to develop different circuits and control of modular practical applications as exercises. Learning Objectives: Having succe...

SPECIFICATION

Objective

Understand & discern the functionality of PLC, interfaces of various devices and components to develop different circuits and control of modular practical applications as exercises.

Learning Objectives:

Having successfully completed this lab, the student will demonstrate knowledge in

- Understand the basic structure of PLC

- Demonstrate a knowledge of PLC programming (Ladder logic)

- Get to known about the different other programming languages (Function chart, Statement list)

- Different Logic techniques in PLC.

- Have basic knowledge of control system

- Understand simple applications of PLC in the industry.

SPECIFICATIONS

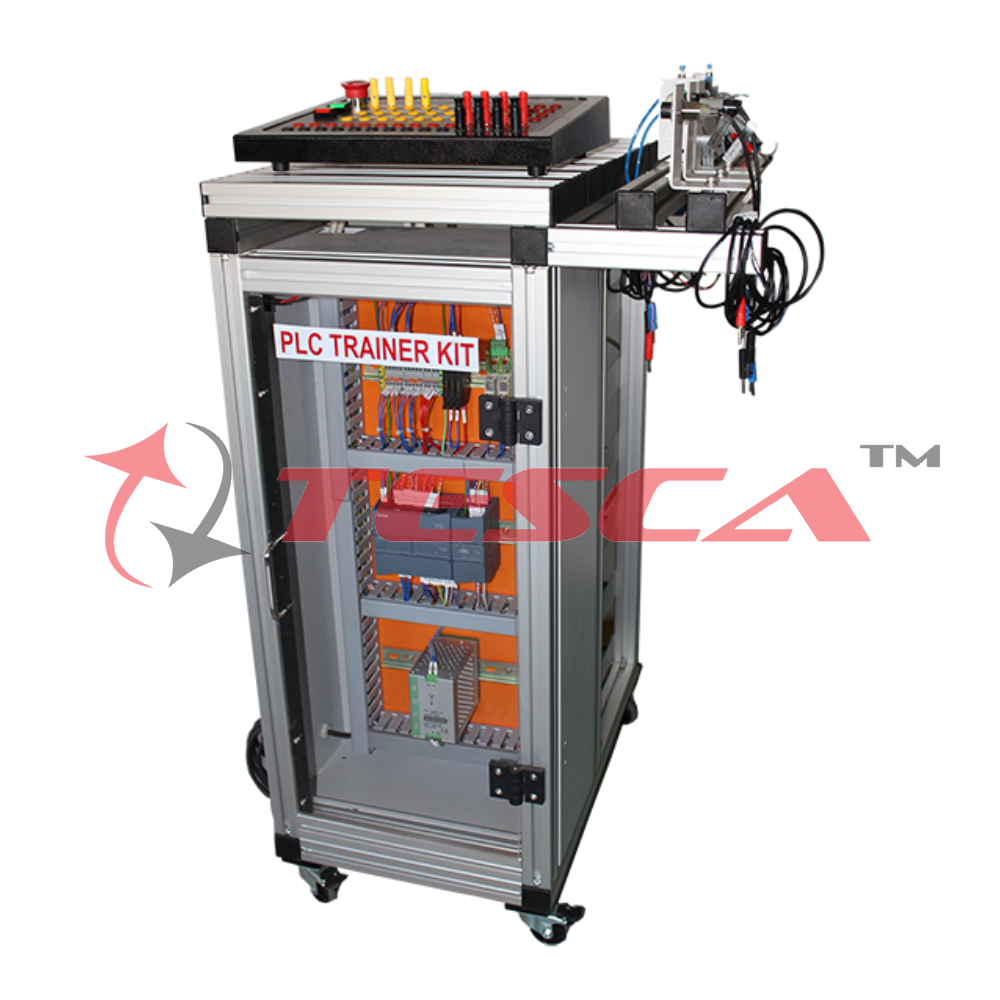

Training Kit : 54026 The PLC Training console has been designed to teach and train the students in the art of programming of different types of PLC’s and execute the programs developed to understand static and simulators. The PLC trainer kit is designed to be a mobile station. The PLC is mounted on the front panel behind a clear door for observation. An operation console is provided that allows the users to wire in the application simulators, transfer program and simulate their programs. The PLC Trainer comes with a series of application modules with increasing level of PLC application. The applications are designed such that the students review the experiment, write their PLC program to generate appropriate result, upload the program to the PLC, plug-n-play the experiment module and run the sequence. The Tesca PLC Trainer is IOT Ready for integration into a cloud application.

Mobile Trolley : The PLC Trainer is self-contained in a Mobile Trolley, built with profile frame on wheels that. The PLC is mounted in an enclosed cabinet in front of the trolley. The mounting surface is a T-grooved plate for positioning the various modules. Built- in shelves allow storage of experiments . This allows for the systems to be moved to different locations such as simulation lab, classroom to lab etc.

Logic Controller : Siemens S7-1200 PLC unit or (Omron PLC optional) 26 Digital input,18 Digital output, 2 Analog Input and 2 Analog output "Process image, 1024 bytes for inputs, 1024 bytes for outputs" Work memory (integrated)-100 KB, Load memory (integrated)-4 MB

Software : TIA Portal V13 step7 for Siemens PLC or (OMRON CX lite programming Software for Omron)

Power supply : Available in PLC control panel(24vdc) IO and Power panel is provided with LED and switch Dia 4mm banana socket for Power and IO connections

Technical Literature : PLC Basic Level Student Work Book - PLC Basic Level Teacher Handbook- Solutions for PLC exercises, Teaching guide for Basic Level of PLC series

MODULES : DESCRIPTION

Process control simulators : Temperature control panel1 Tank filling operation panel1 Flow/gate pump control panel1 Belt conveyor panel1

Others Simulators : Elevator operation and control panel1 Traffic light control panel1 Washing machine operation panel1 Door opening and closing panel1

Sensor Module : Set of inductive, capacitive, optical, magnetic reed switch sensors, micro switches and Pneumatic cylinder to demonstrate the sensor operation and control through PLC.1

Relay Module : "Relay operation-fan and light control panel

Training Objective : Set of 3 No. NC relays with instrument fan and lamps to demonstrate the fan and lamp operation through PLC, Relay logic, NC NO Operation Relay contactor operation, application"1

Star Delta Module : "Star-Delta Motor Start up panel Training

Objective : Set of contactors for starting the 3 phase induction motor. Selection, control circuit, start / delta circuit Forward reverse circuit"1

DIMENSIONS

L x W x H : 920 x 815 x 1450 mm

Weight : 125Kgs (approx.)

REQUIRED EQUIPMENT AT SITE AND UTILITIES TO BE PROVIDED BY THE BUYER DURING COMMISSIONING, DEMONSTRATION & TRAINING

For PLC Trainer

- Compressor - 25 Litre tank Capacity, 6 to 8 Bar (100 – psi) - 1No

- Desktop computer required with specification below

- Operating System : Windows 7 Professional or higher

- Processor Required At least i3 3.3GHz or equivalent, RAM : at least 4 GB

- 19inch LCD Monitor - 1 no

Training Skills–

- To teach PLC mounting, wiring & Operation

- PLC Applications & demonstration.

- PLC Maintenance & Servicing

- Static & Dynamic stand alone modules to explain various logic and system control

- Applications involving from various industries and Automation Systems.

- Preventive & Corrective Maintenance Technology

- Diagnosis of faults & corrective actions

Experiments –

Some of the standalone & practical exercises for the training system are as follows,

- Static Modules – Industrial & Commercial Applications

- Process Flow Control

- Liquid Level Measurement & Control

- Temperature Measurement & Control

- Pressure Measurement & Control

- Force Measurement & Control

- Process Level Control

- Traffic Light Signal Control

- Washing Machine Control

- Lift Operation Control

- Dynamic Modules - Industrial & Commercial Applications

- Relay Module

- Study on types of Relays

- Methodology for Relay logic, operation & control circuit

- Control of practical appliances such as Fan & lamp etc.

- Sensor Module

- Study on principle of Digital & optic sensors

- Methodology of Electrical circuitry,

- Control circuit mounting & analogue signal processing

- Sensors connection & interfacing with PLC.

91-9829132777

91-9829132777