Level Process Control Trainer

Order Code: 52009D.1

Category: Process Control Trainers

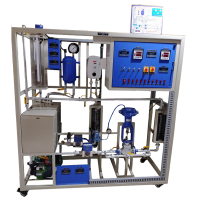

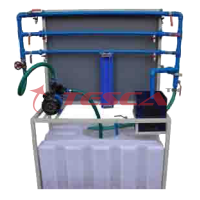

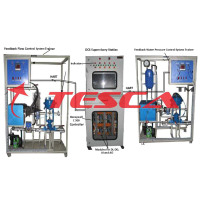

52009D.1 Level Process Control Trainer consists of an instrument panel and transparent tank with different type of level sensor that is useful for the study of principal and working of level measuring setup. This system comprises of the latest compon...

SPECIFICATION

52009D.1 Level Process Control Trainer consists of an instrument panel and transparent tank with different type of level sensor that is useful for the study of principal and working of level measuring setup. This system comprises of the latest components, which reflect the latest technological innovations in this field. Level Process Control Trainer endows students and industry professionals to understand the concepts and working of level Measuring instruments and control, and enables them to learn advance and more complex level process systems.

52009D.1 consists of different types of level Sensors such as Ultrasonic, Capacitance type, Point to Point, Pressure type, Magnetic Float type and DAQ, Solenoid Valve, Sump tank and Acrylic Measuring tank. The set-up has safety measures such as emergency shutdown and overheating protection. A wide range of experiments can be performed on the platform.

Features

Experiments

Technical Specification

52009D.1 consists of different types of level Sensors such as Ultrasonic, Capacitance type, Point to Point, Pressure type, Magnetic Float type and DAQ, Solenoid Valve, Sump tank and Acrylic Measuring tank. The set-up has safety measures such as emergency shutdown and overheating protection. A wide range of experiments can be performed on the platform.

Features

- Included of Different type of Level Sensors like: Ultrasonic, Capacitive type, Point to Point, Pressure type, Magnetic Float type

- 7” Human Machine Interface (HMI)

- Types of Controller : DAQ ,HMI, and PC

- Start, Stop, Pump, Solenoid Valve buttons and Indicator for Visual Indicator, Audio Indicator, Pump & Solenoid Valve

- Industry-standard instruments and controls

- Interface with Ethernet based DAQ

- Sump Tank & Acrylic Measuring Tank

- 8 Channel 24 bit ADC

- Real time DAQ Interface with ADC and Digital input/output

- Academic and vocational study for process control engineers and plant technicians

- Experiments configurable through Patch board

- Self-contained, bench-mounting arrangement

- Supplied with Dashboard Software for supervisory control of the process with data acquisition

- • Castor Wheel (with locking mechanism) is provided at legs of workstation so that it can be easily moved

- MCB is provided with AC supply for safety purpose

- Enhanced electrical safety consideration

Experiments

- Characteristics of Capacitance Type Level Sensor

- Characteristics of Pressure Type Level Sensor

- Characteristics of Ultrasonic Type Level Sensor

- Characteristics of Magnetic Float Type Level Sensor

- Characteristics of Point to Point Type Level Sensor

- Open & close loop function

- ON/OFF controller using software

- Proportional controller using software

- Proportional-Integral controller using software

- Proportional-Integral-Derivative controller using software

- Human Machine Interface (HMI)

- Process Control & Monitor by HMI

- Creating Application/Screen in HMI

- Downloading and Uploading programs

- HMI Communication with PLC

- Creating Alarm Message in HMI

- Creating Trend in HMI

Technical Specification

- DAQ : 1 no. (Data Acquisition System)

- Analog Input : 4 nos.

- Analog Output : 2 nos.

- Digital Input : 6 nos.

- Digital Output : 4 nos.

- ADC Resolution : 24 bit

- Two Unity Gain Amplifier : 0 to 5V

- Ethernet Interface : Yes

- RS485 Interface : Yes

- Data Logging : Yes

- HMI : 1no.(Human Machine Interface)

- Supply : 24V DC

- CPU : 32-bits 400MHz RISC

- Storage : 128M FLASH 64M DDRAM

- Display size : 7 inch

- Resolution : 800×480 TFT LCD 65,536 colors

- Interface : Rs485

- Touch Screen : High precision four-wire resistive

- Type of Level Sensors

- Volumetric Pressure Sensor : 1 no.

- Supply : 90 to 260V AC, 50 Hz

- Accuracy : ± 0.5 % of full scale

- Output : 4 to 20mA, 2 Wire System

- Probe Body : SS-304

- Rating : Rated at 6A, 230VAC for non

- inductive loads

- Housing : Single Channel wall mounting

- Ultrasonic Sensor : 1 no.

- Supply : 5V DC

- Output : 0 to 5VDC

- Range : Upto 5.00M

- Magnetic Float Sensor : 1 no.

- Supply : 24V DC

- Output : 4 to 20mA

- Sensing : Rod Ss304

- Housing : Cast Aluminum weather proof

- Range : 0.5 Meter

- Capacitances Sensor : 1 no.

- Housing Enclosure : Cast Aluminum weather proof

- Supply : 24V DC

- Measurement Span : 15 to 50000 pf above zero

- Response Time : 0.5s to 5 sec

- Accuracy : /-1% FSL

- Output : 4 to 20mA

- Range : 0.5 Meter

- User Interface : 4 Digit display with 4 keys and LED

- Point to Point Sensor : 1 no.

- Supply : 5V DC

- Output : 0 or 5V DC

- Sensing : Rod Ss304

- Digital Panel Meter : 2 nos.

- Display : 4 Digit, 7 segment digital display

- Keys : 3 for Digital Setting

- Input Type : Current

- Resolution : 1 or 0.1 degree

- Supply Voltage : 230V AC

Panel Component Description

- Push to On Switch : 4nos.

- Indicators : 4nos.

- Toggle Switch : 4nos.

- Contactor : 1no.

- Solenoid Valve : 1no.

- Pump : 1no.

- Sump Tank : 1 no.

- Capacity : 100Litters

- Acrylic Measuring Tank : 1no.

- Capacity : 65Litters

- Manual Valve : 3nos.

- Castor Wheel : 4nos (2 with lock & 2 without lock)

- Size : 75mm

- Dimension in mm : H1735 x W1500 x D 740

Included Accessories

- 4mm Patch Cord 18” : 8 nos. (Yellow)

- 4mm Patch Cord 18” : 8 nos. (Blue)

- 4mm Patch Cord 25” : 8 nos.(Red)

- 4mm Patch Cord 25” : 8 nos. (Black)

- Ethernet Cable : 1 no.

- Windows OS Based PC (optional)

Note: Windows OS Based Computer is required to explore DAQ experiments

91-9829132777

91-9829132777