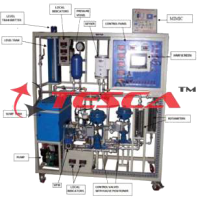

DC Motor Speed Control Trainer. i.e.DC Drive Trainer

Order Code: 52332

Category: Process Control Trainers

The DC Motor Speed Control Trainer i.e. DC DRIVE TRAINER outlines the basics of their operation, Construction and speed control of motor. Features The self contained unit. Modern industrial components are used for operating. Co...

SPECIFICATION

The DC Motor Speed Control Trainer i.e. DC DRIVE TRAINER outlines the basics of their operation, Construction and speed control of motor.

Features

- The self contained unit.

- Modern industrial components are used for operating.

- Comprehensive training manual supplied.

- Optional components are available to allow fault finding.

- Operation and diagnosis training

- Computer interface facility.

- SCADA software for graphical user interface (GUI), Digital data display, redundant bidirectional parameter selection facility, real time Trend plotting historical trends, report generation (Optional)

Technical Specification

- Item Name : Technical Specifications

- PMDC Motor : 12V DC, 1500 RPM, 1.5 Amp, Torque: ½ Kgcm, Mounting Horizontal

- Optical Sensor / Inductive Proximity Sensor : 3 Wire, Sensing Distance: 10cm/ 7mm, 24 VDC

- RPM Indicator/ Tachometer : Speed: 0-1500 RPM, Supply: 230V AC, Cut out size :92 X 92 Retransmission O/P: 4-20mA according 0-1500rpm, 3 ½ digital display.

- DC Drive : Power Supply: 230 V AC, Input: 4-20mA, Output Voltage. 0-12 V DC.

- Voltmeter : Supply:230VAC, 0-20VDC

- Ammeter : Supply:230VAC, 0-2ADC

- Electrical Control Panel : MS Powder coated panel with switches, indicator, test Points, controller on front fascia, UK 2.5 Terminal Connectors mounted on DIN rail channel, Use of 1sq mm multi-strand wire with proper insulated Lugs, Feruling & Neat wire dressing & clamping. Wires & power cables are seated through 1’’×1’’PVC cable tray. Dimension: 1ft (L) ×1ft (W) ×1ft (H)

- PID Controller : With Serial PC Interface (ASCII Protocol) USB / RS 485 / RS 232, Input: 4-20mA, Output:4-20mA, 3½ Digit display, Display: Dual for PV & SP , Bar graph Display for Output & Deviation, High-Low Alarm Annunciation, Cut Out Size: 92mm X 92mm X 144mm

Objectives

- Study of operation, construction of DC motor.

- Study of characteristics of DC motor.

- Study of tachometer.

- Study of DC drive.

- Characteristics plot of Voltage VS Speed, Speed VS Current.

- Study of closed loop control system (speed control).

- Study of P, PI, and PID controllers.

- Study of computerized speed control of DC motor (Optional).

- Study of SCADA SOFTWARE for DC Speed control application (Optional).

- Study torque VS speed for characteristics of DC Motor.

System Components

- DC drive.

- PID controller.

- Tachometer.

- DC motor.

Services Required

- Electric Supply of 1φ 230 VAC, 50Hz

- DC generator or DC supply. (Other supply can be catered for required)

- PC Pentium Dual core for SCADA software analysis for computerized control.(Optional)

System Dimensions: 2 Ft. (L) X 1Ft. (W) X 2 Ft. (H)

Weight: Approx.22 Kg

Note- All descriptive matter and illustrations are intended to give only a general idea of the equipment Detailed specifications may be altered at the company’s discretion without any notice.

91-9829132777

91-9829132777