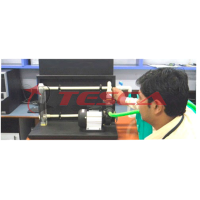

Temperature Control System

Order Code: 52033

Category: Instrumentation Trainers

52033 Temperature control is an important application of control theory to industrial processes. This experiment has been designed to expose the students to such a practical control system, its various stages for control, and the tuning of a PID co...

SPECIFICATION

52033 Temperature control is an important application of control theory to industrial processes. This experiment has been designed to expose the students to such a practical control system, its various stages for control, and the tuning of a PID controller. The process consists of a small and fast responding oven which can be controlled in the temperature range from ambient to about 90°C.

Temperature readings may be taken manually on a 3½ digit meter, mounted on the main unit, at regular intervals. A built-in digital timer having 'START', 'STOP' and 'PAUSE' switches on the panel makes the conduct of an experiment very simple. This design of the oven avoids expensive accessories like an X-Y recorder for conducting the experiment. A forced cooling arrangement has been provided as optional to bring the oven temperature down to room temperature after every experiment. Since the oven may be cooled to the ambient relatively speedily, a number of cycles of experimentation are possible in the usual laboratory hours.

The literature accompanying the unit describes in detail the mathematical concepts, procedure for experiments and a few test results. A number of additional experiments may Also be planned by the teacher using books and literature on this subject which is suggested in the references given.

Object

- Identification of Oven Parameters

- ON-OFF temperature Controller (with adjustable relay characteristics)

- Study of Proportional Controller (P Control) having adjustable coefficients

- Study of Proportional-Integral Controller (PI Control) having adjustable coefficients

- Study of Proportional-Integral-Derivative Controller (PID Control) having adjustable coefficients

Technical Specification

- Temperature controller with facilities for P, I, D and relay control blocks

- Operating temperature: Ambient to 90°C

- Separate controls for P, I, D channel gains

- Two settings for relay hysteresis

- Fast 25W oven fitted with IC temperature sensor

- Forced cooling option to ready oven for next experiment

- Digital display of set and measured temperature on a 3½ digit built-in DVM

- 0-9999 sec, timer on panel for a convenient temperature response experiment

- Buffered output for recorder

- IC regulation in controller circuit power supplies

- Power Supply : 230V ± 5%, 50Hz

- Interconnections : 4mm banana sockets

- Power Consumption: 40 VA (approximately)

- Dimension : W 415 x H 165 x D315

- Weight : 5.2 Kg (approximately)

- Operating Conditions : 0-40 oC, 85% RH

List of Accessories:

- Patch Cord 4mm length 50cm Red..........03

- Patch Cord 4mm length 50cm Black........03

- Temperature Controller Oven..................01

91-9829132777

91-9829132777