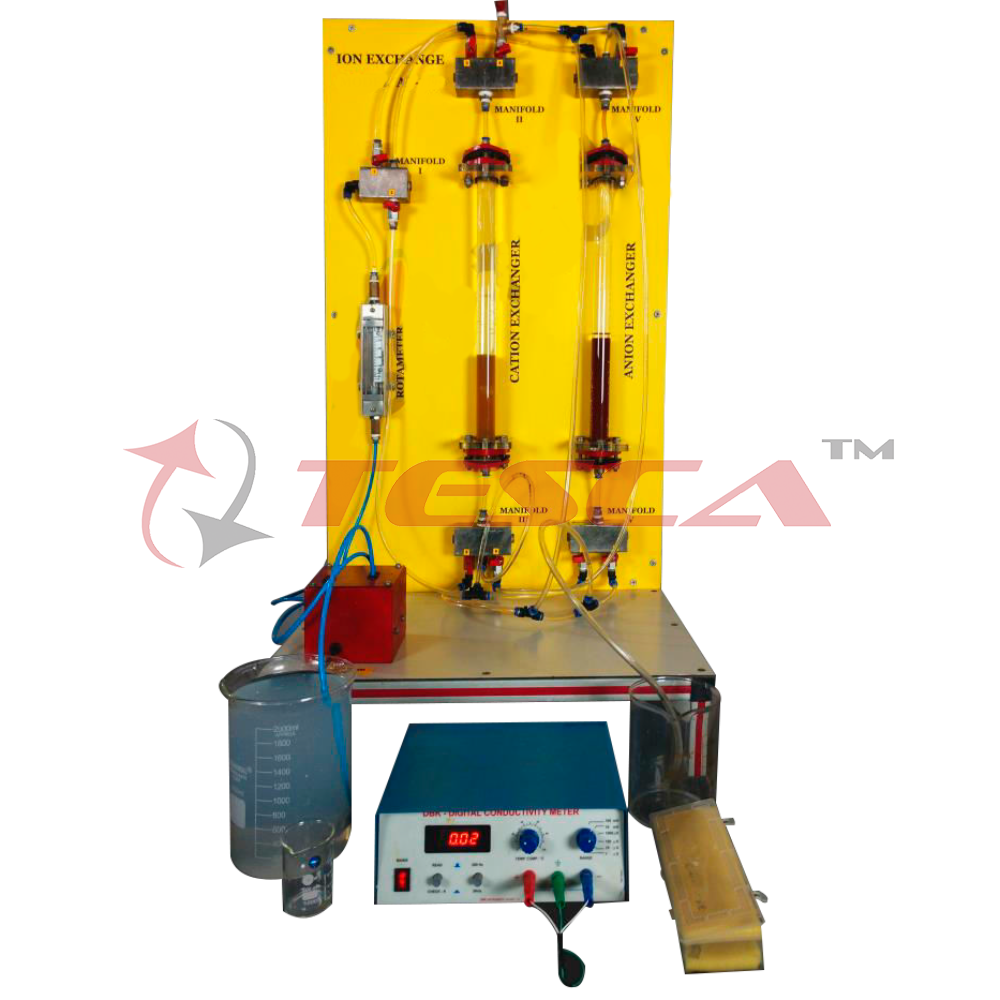

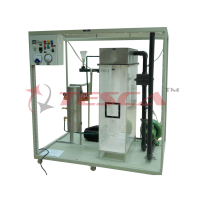

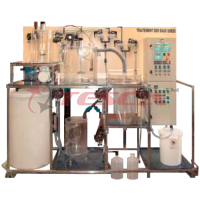

Ion Exchange Chamber

Order Code: 32481

Category: Environmental Trainers

Ion exchangers are used in water treatment primarily for desalination and softening. Tesca Ion Exchange Chamber 32481 enables these processes to be demonstrated with the aid of cation and anion exchangers. The raw water is pumped from the tank into

SPECIFICATION

Features

- Softening and desalination of water by ion exchange

- Regeneration of ion exchangers

- Cation and anion exchanger

Ion exchangers are used in water treatment primarily for desalination and softening. Tesca Ion Exchange Chamber 32481 enables these processes to be demonstrated with the aid of cation and anion exchangers.

The raw water is pumped from the tank into the top of the cation exchanger. In the softening process the water flows from there back into the collecting tank. To desalinate the raw water, it is then additionally routed through the anion exchanger. From there the treated water passes into the collecting tank. In the regeneration process, acid or caustic is fed into the ion exchangers from below using the same pump. The acid and caustic used is collected in the collecting tank.

The flow rate of the pump is adjustable, and can be read from a flow meter before it enters the first ion exchanger. For continuous evaluation of the process, a conductivity sensor is installed upstream of the inlet into the collecting tank. The measured values can be read from a conductivity meter. Samples can be taken at all relevant points. Tap water can be used as raw water.

Specifications

- Softening and desalination with ion exchange

- Cation and anion exchangers usable separately and in combination

- Regeneration of ion exchangers

- Tank with 4 chambers for raw water, rinsing water, acid and caustic

- Diaphragm pump to transport raw water, rinsing water, acid and caustic

- Collecting tank for treated water, rinsing water, acid and caustic

- Continuous measurement of conductivity and flow rate

Technical Specifications

Ion exchanger

- Material: network polymer

- Cation exchanger: H+ form

- Anion exchanger: OH- form

Aphragm pump

- Max. flow rate: 300mL/min

- Max. head: 10m

Tank

- 4 chambers

- capacity: each approx. 5L

- material: PVC

Collecting tank

- capacity: approx. 20L

- material: PVC

Measuring ranges

- flow rate: 20…270ml/min

- conductivity: 0…2000μS/cm

Experiments:

- Learning the fundamental principle of softening and desalination by ion exchange

- Identification of the different modes of operation of cation and anion exchangers

- Combined use of cation and anion exchangers for desalination

- Exchanging capacities and regeneration

- Verification of the theoretically calculated regeneration time

Requirements

Mains Power 220 – 240V @ 50Hz, 1Ph

91-9829132777

91-9829132777