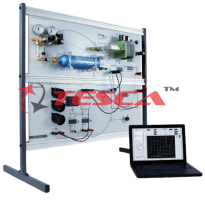

UV Filter Drinking Water System Demo Panel

Order Code: 32504

Category: Other Trainers

Ultraviolet Irradiation Technology Ultraviolet (UV) irradiation technology is primarily used in the water and wastewater treatment industry as a disinfection process that capitalizes on the germicidal effect of UV light in the wavelength range of 25...

SPECIFICATION

Ultraviolet Irradiation Technology

Ultraviolet (UV) irradiation technology is primarily used in the water and wastewater treatment industry as a disinfection process that capitalizes on the germicidal effect of UV light in the wavelength range of 250 to 270 nm (EPA, 1996). The process is commonly designed such that water flows in a narrow region around a series of UV lamps. The microorganisms in the water are inactivated through exposure to the UV light. The process is compact since the time of exposure (which translates into hydraulic retention time) is commonly measured in seconds. The process works on the principle that UV energy disrupts the DNA of the microorganisms and prevents it from reproducing.

There are four types of UV technologies of interest to the water industry: low-pressure, low-intensity (LP-LI) UV technology; low-pressure, medium-intensity (LP-MI) UV technology; medium-pressure, high-intensity (MP-HI) UV technology; and pulsed-UV (PUV) technology. Approximately 90 percent of the UV installations in North America have LP-LI UV technology, with some dating back to the 1970s. The power output of LP-LI UV lamps commonly varies from 40 to 85 W. Another unique characteristic of low-pressure lamps is that they emit a monochromatic light at a wavelength of 254 nm. EPA's design manual is specifically based on and tailored to LP-LI UV technology. The primary advantage of LP-LI UV lamps is their high efficiency. The primary disadvantage is their low power, which results in the need for a large number of lamps for a small plant. For example, a typical secondary wastewater effluent would require approximately 40 LP-LI UV lamps per MGD of peak capacity. Considering that a significant labor effort is required to clean and maintain UV lamps, the application of LP-LI UV technology at large scale is not desirable.

LP-MI UV lamps are identical to LP-LI UV lamps with the exception of a higher power output--170 W compared to 40 to 85 W. Therefore, a typical secondary wastewater effluent would now require only 20 to 24 lamps per MGD of capacity. This makes LP-MI UV technology more applicable for medium-size water treatment facilities than LP-LI UV technology.

MP-HI UV lamps operate at substantially higher gas pressure inside the lamps compared to low-pressure UV lamps and are characterized by a power output that varies from 5 to 30 KW. Contrary to low-pressure lamps that produce all of their light at approximately 254 nm, medium-pressure lamps produce a polychromatic light, of which only 25 percent is in the germicidal wavelength range of 200 to 300 nm. However, because of the higher power output of MP-HI UV lamps, UV disinfection systems using this technology are substantially smaller than those using LP-LI UV technology, simply because of the need for significantly fewer lamps. The new UV technology under development is pulsed UV technology. In this process the energy is stored in a capacitor and then released to the lamp in a short, high-intensity pulse. The duration between pulses is approximately 30 milliseconds, and each pulse lasts for less than 1 millisecond. The intensity of each pulse is believed to be about 107 mW/cm2. One manufacturer of this technology claims that the high energy emitted with each pulse is far more effective for the inactivation of microorganisms compared to the same level of energy emitted over an extended period of time. Figure 11-5 shows a plot of the inactivation rate of MS2 bacterial virus with pulsed UV and LP-LI UV systems. The results suggest that, for the same UV dose, pulsed UV systems may achieve approximately one log additional kill of MS2 virus compared to that achieved by traditional LP-LI UV. However, questions remain about the ability to accurately measure the UV dose emitted by a pulsed UV system.

Technical Specifications Pump

Max. flow rate: 1m3/h

Max. head: 20m

Tank: 10L

Filter

Low UV

Measuring ranges

Flow rate: 10-80L/h

Temperature: max. 80

Requirements

Water Source & Water Flushing system

Mains Power 220-240V@50Hz, 1 Phase

91-9829132777

91-9829132777