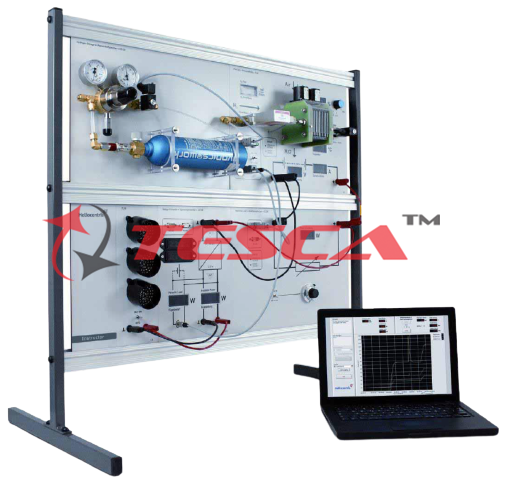

PEM Fuel Cell Trainer

Order Code: 32501

Category: Other Trainers

Specifications Investigation of a polymer-membrane fuel cell Water cooled system in combined heat and power Hydrogen supplied via standard pressure vessel High-pressure reducing valve for hydrogen pressure vessel suppl...

SPECIFICATION

Specifications

Investigation of a polymer-membrane fuel cell

Water cooled system in combined heat and power

Hydrogen supplied via standard pressure vessel

High-pressure reducing valve for hydrogen pressure vessel supplied

Oxygen supplies directly from the ambient air

Precise adjustment of all operating points via electronic load

Operation without external humidification

Sensors for flow rate, pressure, temperature, voltage and current strength

Complete operation and evaluation via a PC Software with control functions and data acquisition via Windows 7, 8.1, 10

Water-cooled / Air cooled polymer-membrane fuel cell combined heat and power

Integrated control and monitoring of all operating and safety parameters

Fuel cells are energy converters that, unlike heat engines, convert chemical energy directly into electrical energy. Heat is generated as a by-product during this process. The main component of PEM Fuel Cell Trainers Order Code : 32501 is a polymer- membrane fuel cell which is operated in combined heat and power generation. The system is supplied with high-purity hydrogen from a pressure vessel on the anode side and with oxygen from the ambient air on the cathode side. The fuel cell is operated either current-regulated or voltage-regulated via an integrated electronic load. The set-point of the electronic load allows a precise adjustment of all operating points and a very accurate recording of characteristics. The technically usable thermal energy is dissipated to the environment via a cooling circuit and can be accounted for via the integrated instrumentation. The water accruing during operation is collected in a water separator. In the fuel cell’s dead- end mode the accruing water is disposed of via a configurable purge valve for hydrogen. The system is operated via a PC. Auxiliary energy for pump, fan and control required for operation is provided from the mains. The moisture in the stack can be regulated via adjustment of the purge valve, so that no external humidification is required. All relevant measuring values are recorded to work out the fuel cell’s energy balance. The measured values are transmitted directly to a PC via USB. The Sci-tech data acquisition software is included.

Technical Specifications

Nominal output: 100W/250W/500W/1000W

Thermal power: approx. 150 ~ 200% depending on ambient conditions

Required ambient temperature: 5…35°C

Required inlet pressure: 2…200bar

Measuring ranges Flow Rate:

0…0,5L/min (cooling water)

0…20sL/min (hydrogen)

0…100sL/min (air)

Pressure: 0…500mbar (hydrogen)

Temperature:

0…50°C (ambient)

0…70°C (stack)

Humidity: 0…100% (ambient)

Voltage: 0…40V (stack)

Current: 0,1…20A (stack)

Experiments

Conversion of chemical energy into electrical and thermal energy

Function and design of a fuel cell system

Relationships of fuel cell operating parameters

Effects on the electrical performance of fuel cells

Recording and visualization of all relevant voltage/current characteristics

calculation of relevant variables

Requirements

Mains Power 220 – 240V @ 50Hz, 1Ph & 400 – 440V @ 50Hz, 3Ph

91-9829132777

91-9829132777