Water Chiller Training Unit

Order Code: 32438

Category: Refrigeration & Air Conditioning Lab

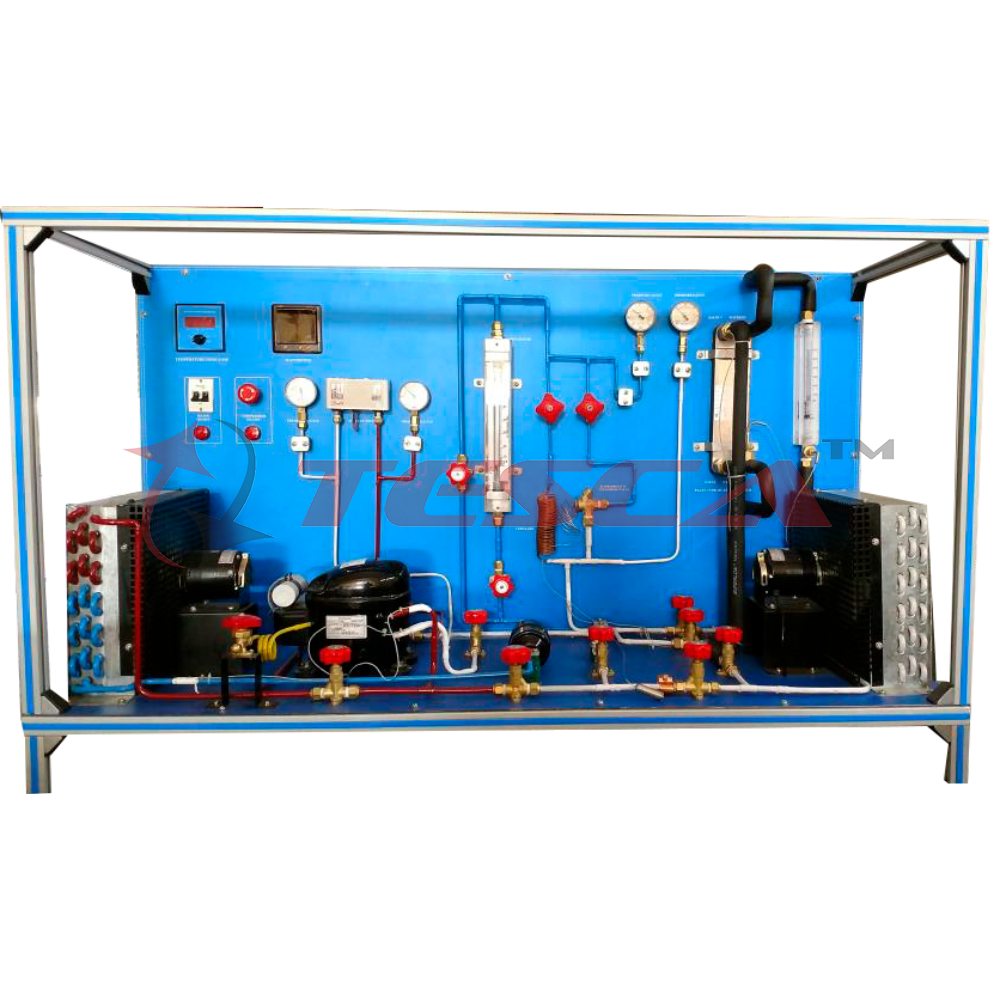

Tesca Water Chiller Training Unit 32438 is a fully operational, water chiller, which enables the student to adjust and investigate a typical water cooler operating under load, either with or without evaporator pressure regulation. The cooling of pur

SPECIFICATION

Features

- Fully Operational Water Chiller With Cooling Load

- Evaporator Pressure Regulator to Demonstrate Non- Freeze Cooling

- Optional Data Acquisition Available.

Tesca Water Chiller Training Unit 32438 is a fully operational, water chiller, which enables the student to adjust and investigate a typical water cooler operating under load, either with or without evaporator pressure regulation.

The cooling of pure water requires that the evaporator surface temperature does not fall below 0°C or the system will freeze and may result in damage. This unit allows students to safely explore the parameters affecting evaporating pressure without danger to the operator or equipment.

As with all Tesca vocational equipment all of the components are clearly arranged on a panel allowing easy identification.

Components include:

- Hermetic compressor

- Water cooled condenser with adjustable pressure control

- Liquid receiver

- Water cooling evaporator

- Adjustable evaporator pressure regulation

- Suction accumulator

- Cooling load, adjustable in steps of 1.0 and 0.5kW

- Adjustable cooling water flow

- Pressure, temperature and flow rate measurement.

- Control panel that will accept optional computerized data acquisition.

The trainer has been carefully designed to provide instruction in specific topic areas that trainees are required to study as part of most Refrigeration and Air Conditioning courses.

The unit is mounted on a steel frame with metal panels and comprises an hermetic compressor with water cooled condenser, liquid receiver, water cooling evaporator with adjustable pressure regulator.

A pump circulates the cooled water at an adjustable flow rate through a tank with individually switched heaters that load the refrigeration system.

Instrumentation includes condenser and suction pressure gauges, evaporator pressure (service gauge), digital temperature indicator with 10 way selector switch, evaporator and condenser flow rate measurement, optional refrigerant flow meter and optional computerized data acquisition system for all parameters including compressor current.

All the controls and the high and low-pressure switches are adjustable by the student to enable advanced studies in the control of vapour compression refrigeration equipment.

Specifications

The unit is mounted on a steel framework, with metal base and back panels and incorporates:

- Hermetic compressor

- Water-cooled condenser.

- Liquid receiver

- Adjustable condenser pressure regulator

- Water-cooling evaporator

- Thermostatic expansion valve

- Adjustable evaporator pressure regulator with detachable service gauge.

- Suction accumulator.

- Water tank with individual switchable loads of 1kW, 1kW and 0.5kW

- Water circulating pump with flow control.

Instrumentation includes:

- Digital temperature indicator with 10 way selector switch.

- Condenser and evaporator water flow meters.

- Condenser and suction pressure gauges and detachable evaporator pressure gauge.

- Optional refrigerant flowmeter.

Control panel includes

- Overload protection

- Contactor

- Earth leakage protector

- Optional computerized data acquisition system.

Requirements

220 – 240V, 50Hz, 1 phase Power Supply

91-9829132777

91-9829132777