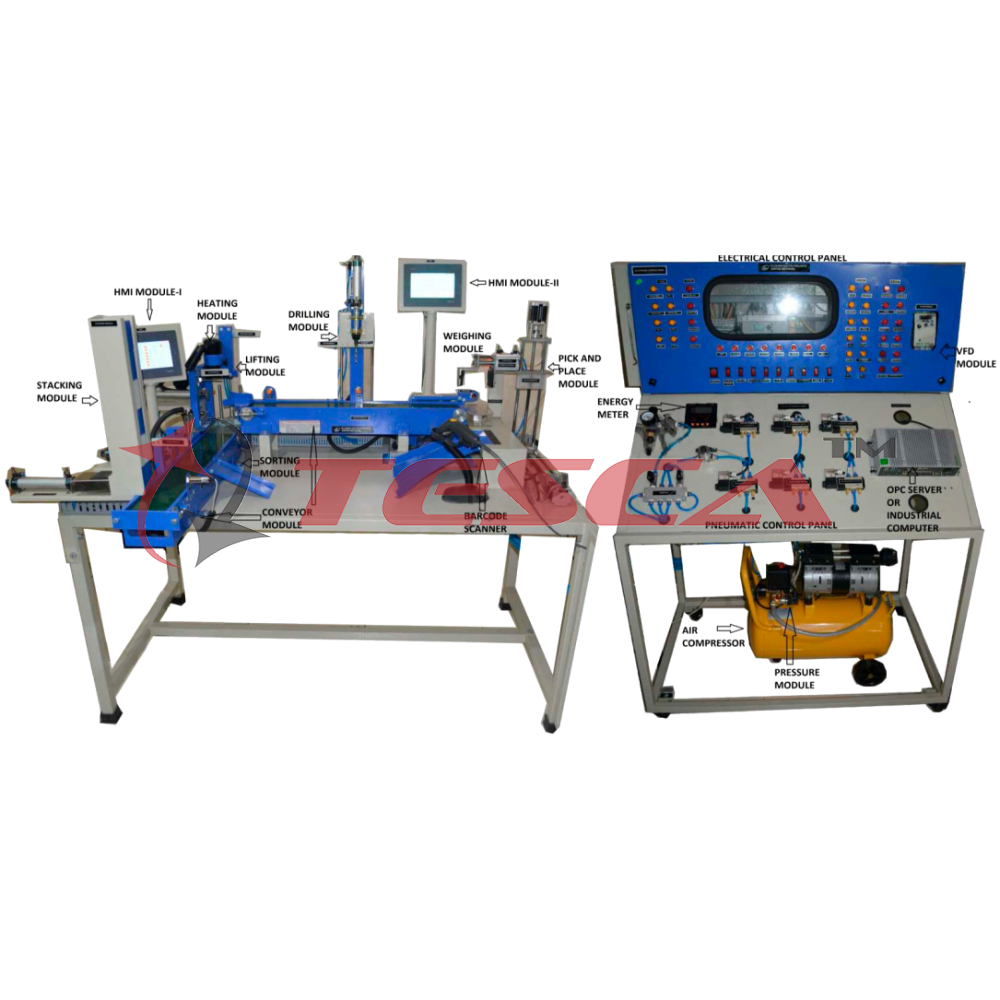

Mechatronics Trainer Kit - IOT Based Industrial Process Demonstration Plant

Order Code: 52387

Category: Process Control Trainers

The IOT BASED INDUSTRIAL PROCESS DEMONSTRATION PLANT provides you with the perfect method for teaching automation technology step by step – from simple procedures right through to complex processes based on the principles of Industry ...

SPECIFICATION

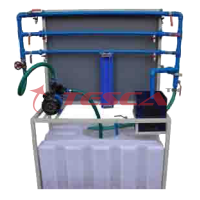

The IOT BASED INDUSTRIAL PROCESS DEMONSTRATION PLANT provides you with the perfect method for teaching automation technology step by step – from simple procedures right through to complex processes based on the principles of Industry 4.0. The modular design is therefore useful for imparting knowledge and practical experience and is equally suitable for initial operational training and advanced technical training. Various functional assemblies(like two belt conveyor beds, stacking assembly, heating module, drilling assembly, weighing platform), a robotic pick & place arm assembly and two control systems (PLCs) are mounted on the mobile powder coated metal trolleys. This configuration allows the user to implement various automated processes. The processes undergone by the work pieces are controlled by the Barcode labels put on the work pieces which are read by barcode scanners. One section of the system can be removed to reduce the overall process. The whole process data is locally monitored on HMI’s, stored on local computer system as well as uploaded on cloud & can be remotely accessed for DATA ANALYSYS for OPTIMAL PLANT OPERATION thereby increasing productivity, Efficiency & profitability.

Features:

Features:

- Compact Ergonomic Design.

- Data can be locally monitored, stored and uploaded on cloud using OPC server and can be remotely accessed, monitored for data analysis.

- Inbuilt Safety Measures to avoid improper usage.

- Training Manual, mimic Charts for Operation Ease.

- Detailed Operation & Instruction Manual

- System Frame with Caster Wheel Arrangement for ease in movement.

- User Friendly, Self Explanatory Systems.

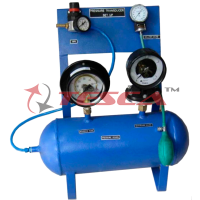

- Leak proof Safety Measures, sturdy piping & Robust Construction.

- M.S. fabricated powder coated with necessary fittings & Pneumatic Connections.

- Integration of Electronic, Instrumentation and Pneumatic in single unit.

- All Pneumatic components identical to those used in industry.

- Caster wheel mounted movable frame

Services Required:

- Electric supply 230 V AC, 50 Hz.

91-9829132777

91-9829132777