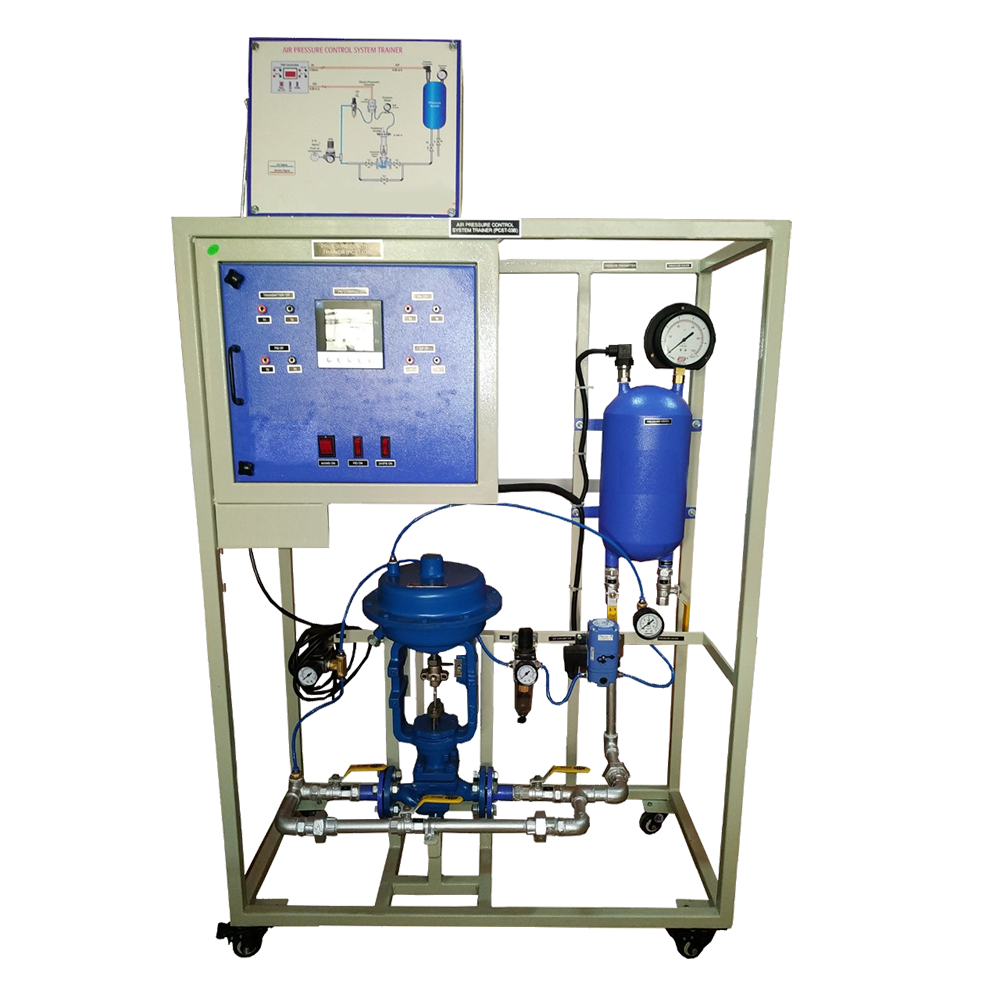

Pressure Control Trainer (Air)

Order Code: 52229

Category: Process Control Trainers

The Air Pressure Control Trainer is the system which outlines the basics of Closed Loop Air Pressure Control and various aspects related to it. KEY WORDS: Feedback Air Pressure Control. ON-OFF & PID control. SCADA Based AIR...

SPECIFICATION

The Air Pressure Control Trainer is the system which outlines the basics of Closed Loop Air Pressure Control and various aspects related to it.

KEY WORDS:

- Feedback Air Pressure Control.

- ON-OFF & PID control.

- SCADA Based AIR PRESSURE Control.

- TRANSIENT response analysis study.

- OPEN/CLOSE loop response.

- MANUAL/AUTO tuning of controller

- USB/RS232/RS 485/ Ethernet/ Modbus Communication.

- P, P I, P I D Controller Action.

- Ability to hook up with DCS (Distributed Control System Trainer)

Range of experiments:

- Study of single loop Feedback Proportional (P), Integral (I) and Derivative control (D) actions.

- Study of operation and calibration of transmitters, I/P converter and Control Valve.

- Study of OPEN LOOP/CLOSE LOOP TUNNING & AUTO TUNNING of controller.

- Study of STEP response & Transient response of controller ( process curve).

- Study of tuning and operation of PID controller.

- Study of stability of single loop AIR PRESSURE Control System.

- Configure microcontroller based controller to give manual output, changing controller modes (Manual/Auto), Checking ON-OFF, Proportional, Integral, Derivative, PI and PID control actions, change local Set point, configure and run a set point ramp, configure measured values to either percentage or Engineering units.

- Study of Communication Protocols and interfacing of System with DCS / SCADA etc..

- Study of SCADA Application Software/ Computerized Control of Air Pressure Control System.

Features:

- Illustrates the concept of feedback AIR PRESSURE control loop.

- User Friendly, Self Explanatory Systems.

- Leak proof Safety Measures, sturdy piping.

- Enhanced Electrical Safety Considerations.

- Training Manual & Mimic Charts for Operation Ease.

- System Frame with Caster Wheel Arrangement for ease in movement.

- M.S. powder coated cubical plant with standard Instrument Mountings.

- Inbuilt Safety Measures to avoid improper usage.

- Computer Interface (Optional), SCADA Application software connectivity for analysis of Air Pressure

91-9829132777

91-9829132777