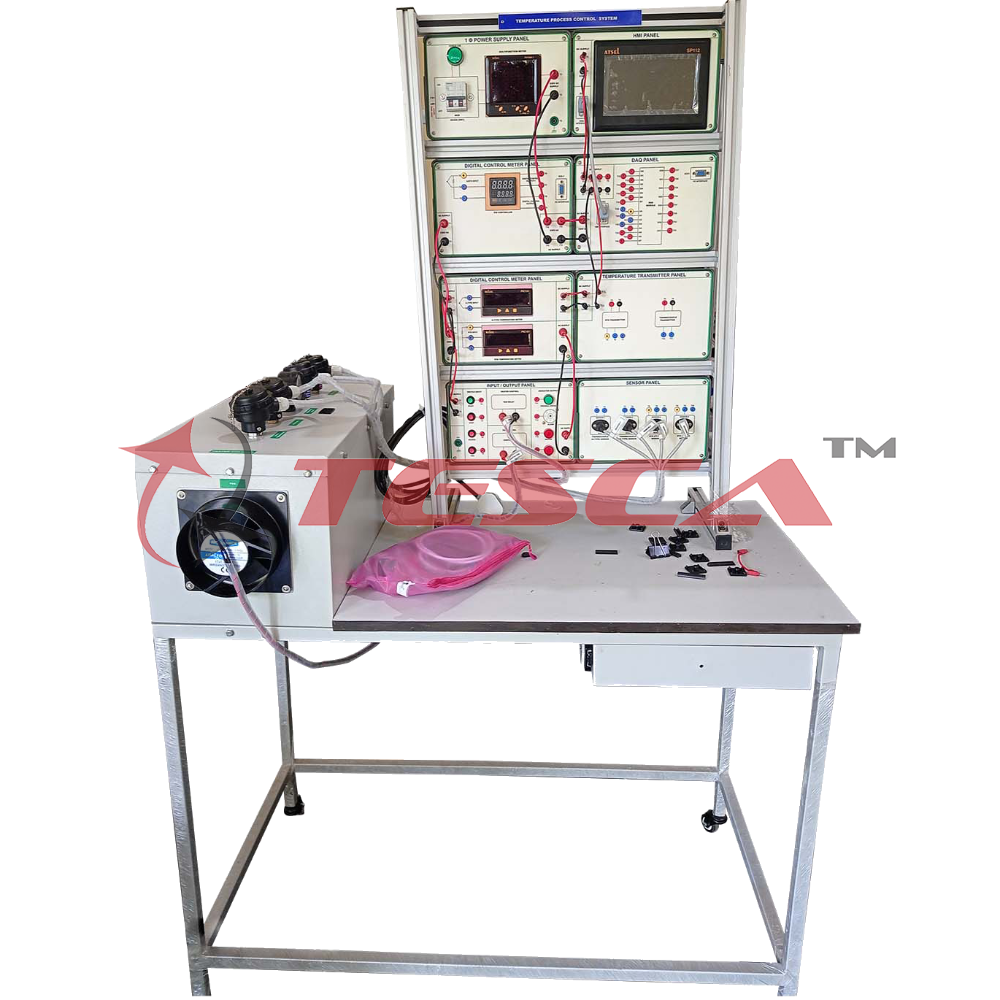

Temperature Process Control Trainer

Order Code: 52009A.1

Category: Process Control Trainers

52009A.1 In this world driven by technology, instrumentation & control engineering drives industrial growth, whilst process control is a vital concept of it. The functionality and complexity of Process Control has increased. Temperature Pr...

SPECIFICATION

52009A.1 In this world driven by technology, instrumentation & control engineering drives industrial growth, whilst process control is a vital concept of it. The functionality and complexity of Process Control has increased.

Temperature Process Control Trainer consists of an instrument panel and working area. This system comprises of latest components, which reflect the latest technological innovations in this field. Temperature process control trainer allow user and industry professionals to understand the concepts and working of temperature measuring instruments and control.

52009A.1 is a complete setup to control process through two point (On/Off) and three point (PID) controllers. Temperature can be controlled through an DAQ which has 8 digital inputs and 8 digital outputs and 8 analog inputs. 52009A.1 also gives the exposure to Industrial components like Temperature Transmitter, Temperature Sensor, Thermocouple, RTD, PID controller, Radiation Pyrometer, and Heater etc. Users can learn how to install, operate, program and tune the instruments for controlling the processes. All electrical components are connected to the control panel to allow user to measure signals and connect devices in wide variety of control configuration including open loop (manual control) and close loop (PID control, ON/OFF control).

Features

Experiments

Temperature Process Control Trainer consists of an instrument panel and working area. This system comprises of latest components, which reflect the latest technological innovations in this field. Temperature process control trainer allow user and industry professionals to understand the concepts and working of temperature measuring instruments and control.

52009A.1 is a complete setup to control process through two point (On/Off) and three point (PID) controllers. Temperature can be controlled through an DAQ which has 8 digital inputs and 8 digital outputs and 8 analog inputs. 52009A.1 also gives the exposure to Industrial components like Temperature Transmitter, Temperature Sensor, Thermocouple, RTD, PID controller, Radiation Pyrometer, and Heater etc. Users can learn how to install, operate, program and tune the instruments for controlling the processes. All electrical components are connected to the control panel to allow user to measure signals and connect devices in wide variety of control configuration including open loop (manual control) and close loop (PID control, ON/OFF control).

Features

- 7” Human Machine Interface (HMI)

- Types of Controller DAQ, HMI & Industrial PID Controller

- Temperature Transmitter for RTD & Thermocouples

- Industrial RTD & Thermocouple Sensor

- Start, Stop, Heater, Fan button. Indicators for Audio, Visual, Heater and Fan

- Interface with Ethernet based DAQ

- Real-time DAQ interface with ADC, DAC & digital input/output

- Supplied with Dashboard Software for supervisory control of the process with data acquisition

- PC Based Data Logging

- Temperature Measurement and control

- Heavy duty WorkStation

- Electrical control panel

- SCR Power Controller for Heater

- Automatic and Manual control

- Process Control by On/Off Controller

- Process Control by PID with auto tuning

- Process loop tuning & stable process

- User friendly, self explanatory system

- Practice troubleshooting skills

- Experiments configurable through patch board

- Enhanced electrical safety considerations

- Caster wheel (with locking mechanism) at the legs of WorkStation for easy movement

- MCB provided with AC supply for safety purpose

- Academic and vocational study for process control engineers and plant technicians

Experiments

- Characteristics of Capacitance Type Level Sensor

- Characteristics of Pressure Type Level Sensor

Technical Specification

Data Acquisition System : 1 no.

- Analog Inputs : 8 nos.

- Digital Inputs : 8 nos.

- Digital Outputs : 8 nos.

- ADC Resolution : 24 Bit

- RS485 Interface : Yes

- Ethernet Interface : Yes

- Data Logging : Yes

Human Machine Interface (HMI) : 1 no.

- Supply : 24V DC

- CPU : 32-bits 400MHz RISC

- Storage : 128M FLASH 64M DDRAM

- Display size : 7 inch

- Resolution : 800×480 TFT LCD 65,536 colors

- Interface : Rs485

- Touch Screen : High precision four-wire resistive

Industrial PID Controller : 1 no.

- Supply Voltage : 230V AC

- Input : Accuracy 0.2%FS

- Thermocouple : K Type

- RTD : Pt100

- Output : 4 to 20mA, Relay

- Control Algorithms : PID, P, PI, PD, On/Off

- PID Range :

- P : 0 to 200%

- I : 0 to 3600 Sec

- D : 0 to 900 Sec

- Communication : Rs485

Temperature Display : 2 nos.

- Display : 4 Digit, 7 segment digital display

- Keys : 3 for digital setting

- Input Type : RTD (PT100) & Thermocouple

- Resolution : 1 or 0.1 degree

- Temperature Unit : Degree C

- Supply Voltage : 230V AC

- RTD Sensors : 2 nos.

- Type : RTD (Pt100)

- Wire : 3 wire

- Rod Length : 6”

- Temperature Range : (-99 to 850°C)

- Thermocouple Sensors : 2 nos.

- Type : K Type

- Wire : 2 Wire

- Rod Length : 6”

- Temperature Range : -200 to1250°C

Temperature Transmitter RTD : 1 no.

- Range : 0-2000 C

- Output : 4 to 20mA

- Type : Head mounted

- Input : RTD (Pt100), 3 wire

- Loop Supply : 24V DC nominal (12 to 36)V DC

Temperature Transmitter Thermocouple :1 no.

- Range : 0-2000 C

- Output : 4 to 20mA

- Type : Head mounted

- Input : Thermocouple (K Type)

- Loop Supply : 24V DC nominal (12 to 36)V DC

- Radiation Pyrometer : 1 no.

- Temperature Range : -30°C to 350°C (-22 °F to 662 °F)

- Response Time (95 %) : <500 ms (95 % of reading)

- Distance to spot ratio : 8:1 (calculated at 90% energy)

- Display resolution : 0.1 °C (0.2 °F)

- Power : 1 AA IEC LR06 battery

Panel Component Description

- Digital Multimeter : 1 no.

- DC Voltage : 0.1mV ~ 1000V

- AC Voltage : 0.1 mV ~ 750V

- DC Current : 0.1uA ~ 20A

- AC Current : 0.1uA ~ 20A

- Capacitance : : 10pF ~ 200uF

- Resistance : 0.1%u2126 ~ 40M%u2126

- Frequency : 0.1Hz ~ 30MHz

Multifunction Meter : 1 no.

Voltage : 10 - 230Vrms, Accuracy ± (1% reading 2 digits)

Current : 0.2 - 5Arms, Accuracy

± (1% reading 2 digits)

Active Power : 10-1500Watt, Accuracy ± (2% reading 3 digits)

Push to on Switch : 4 nos.

Toggle Switch : 3 nos.

Indicator Lamp : 4 nos.

SSR (SCR Power Controller): 1 no.

- Heater : 1 no.

- Power : 1000W

- Supply : 230 V AC (1500Watt)

- Fan : 2nos.

- Supply : 230V AC

- MCB : 1no.

- Supply : 230V AC

- Current : 16Ampere

- Contactor : 2 nos.

- Supply : 230V AC

- Power Indicator : 1 no

- Caster Wheel : 4 nos. (2 with lock & 2 without lock)

- Size : 75mm

- Mercury Thermometer : 2 nos.

Experiments

- DAQ Digital Input

- DAQ Digital Outputs

- DAQ Analog Inputs

- RTD Characteristics

- Thermocouple Characteristics

- RTD Temperature Transmitter Characteristics

- Thermocouple Temperature Transmitter Characteristics

- RTD & Thermocouple Temperature measurement using Process Indicator.

- Temperature measurement using Radiation Pyrometer

- Set-Alarm using software

- On/Off controller using Software & Industrial PID Controller

- Proportional controller using Software & Industrial PID Controller

- Proportional-Integral controller using Software & Industrial PID Controller

- Proportional-Integral-Derivative controller using Software & Industrial PID Controller

- Process Control & Monitor by HMI

- Creating Application/Screen in HMI

- Downloading and Uploading programs in HMI

- HMI Communication with DAQ

- Creating Alarm Message in HMI

- Creating Trend in HMI

Included Accessories

- 4mm Patch Cord 30” : 5 nos. (Red)

- 4mm Patch Cord 30” : 5 nos. (Black)

- 4mm Patch Cord 30” : 5 nos. (Yellow)

- 4mm Patch Cord 30” : 5 nos. (Blue)

- 4mm Patch Cord 18” : 10 nos. (Yellow)

- 4mm Patch Cord 18” : 10 nos. (Blue)

- Ethernet Cable : 1 no.

Universal Calibrator (Optional)

- Type : Sourcing and measuring

- Display : 5 digit, 7segment LCD

- Resolution : 0.1%u2126,1ua, 1µV,1mV

- Accuracy : ± 0.02% of rdg ± 0.01% of FS ± 2

- Range : 2000%u2126, 20mA, 200mV, 20V RTD (Resistance Temperature Detector) Sensor

Windows OS Based PC (optional)

Note: Windows OS Based Computer is required to explore DAQ experiments

91-9829132777

91-9829132777