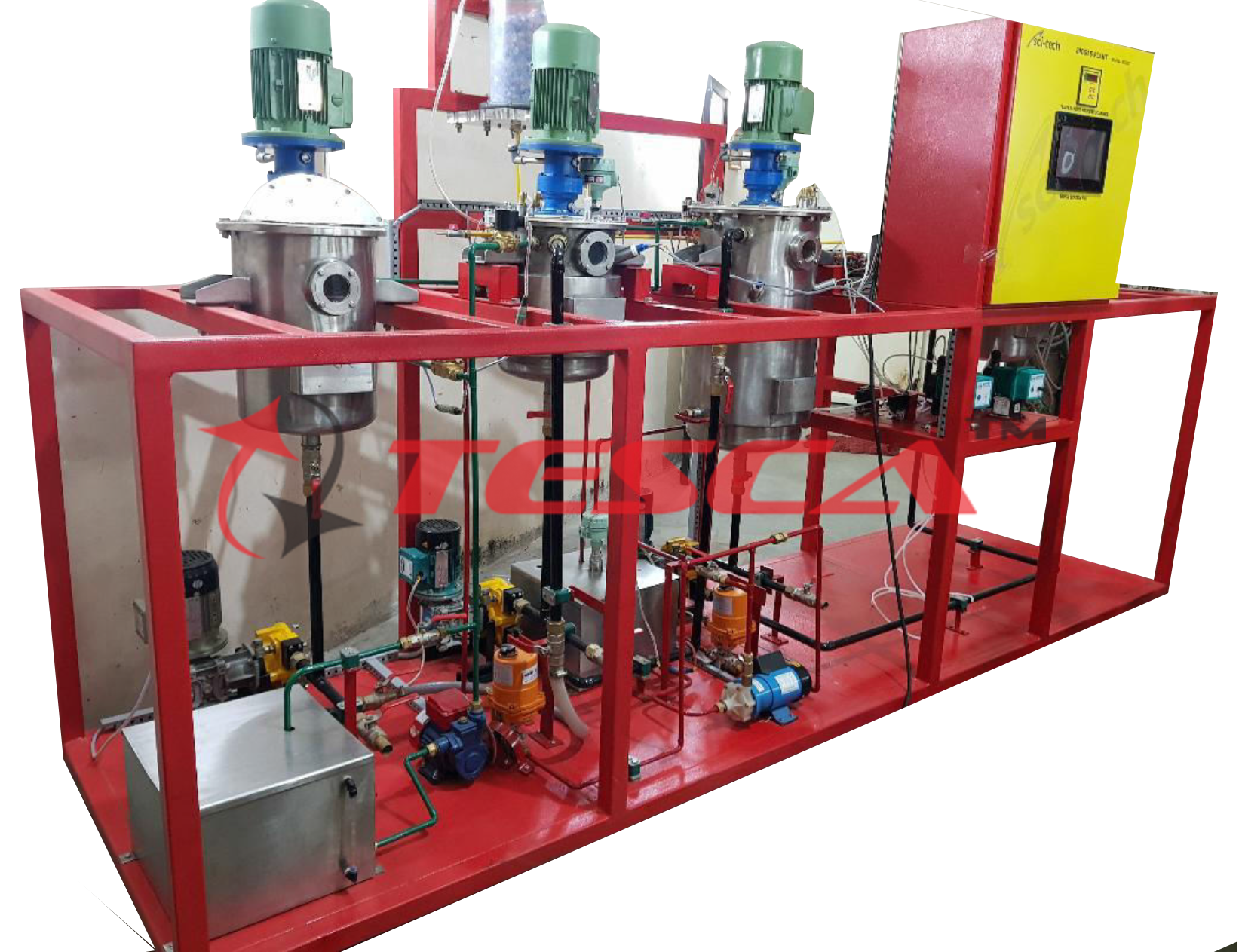

Bio Diesel Plant

Order Code: 32500

Category: Other Trainers

Features Chemical transesterification Two-stage process Plant controlled via PLC and touch panel The use of renewable energy carriers in the mobility sector can happen by replacing fossil fuels. One option is biodiesel, which is obtained from veg...

SPECIFICATION

Features

Chemical transesterification

Two-stage process

Plant controlled via PLC and touch panel

The use of renewable energy carriers in the mobility sector can happen by replacing fossil fuels. One option is biodiesel, which is obtained from vegetable oils. It is produced by adding methanol and potassium hydroxide (as catalyst) and is a transesterification, a chemical equilibrium reaction. On a large industrial scale, production is carried out continuously in stirred tank reactors. This process is demonstrated on a small scale by Bio Diesel Plant Order Code : 32500 experimental plant. The chemical reaction takes place at temperatures of around 60°C. The products leave the reactor after a predefined dwell time. The products are a two-phase mixture: A biodiesel-rich phase and a phase with byproducts. The by-products are pumped out of the following phase separator. The options for the biodieselrich phase are: Return to the reactor, second transesterification stage, methanol recovery (distillation) and biodiesel washing (absorption). The biodiesel-rich phase contains residual amounts of methanol, potassium hydroxide and vegetable oil, in addition to the biodiesel. The remaining vegetable oil is reacted in the second transesterification stage. The methanol is distilled off in the methanol recovery stage. Residual amounts of the catalyst are removed in the biodiesel washing stage. Then the products are stored. The rate of transesterification is dependent on the reaction time and the temperature. The chemical equilibrium is shifted by the separation of the by-products. The biodiesel produced is analysed in the laboratory. The process parameters can be varied to investigate the dependencies. The experimental plant is controlled by a PLC, which is operated by means of a touch panel. Software takes care of data acquisition.

Specifications

1. Chemical transesterification of vegetable oils

Two-stage, continuous process

Two heated stirred tank reactors for chemical transesterification

Two phase separators for separating products and by-products

Methanol recovery (distillation) to reduce the amount of methanol required

Biodiesel washing (absorption) to extract impurities from the biodiesel

Variation of process parameters to investigate the dependencies of biodiesel production

Optional PLC for controlling the experimental plant

Optional touch panel for operating the PLC

Optional software for data acquisition via USB under Windows 7, 8.1, 10

Technical Specifications Tanks

Stirred tank reactors: 2x 5L

Storage tank (vegetable oil): 110L

Storage tank (chemicals): 45L

Product tank: 110L

By-product tank: 45L

Methanol tank: 6L

Phase separator/biodiesel washer: 3x 15L

Peristaltic pumps: max. 25L/h

Measuring ranges

Temperature: 6x 0…100°C Ÿ Pressure: 1x 0…6bar (abs.) Ÿ Flow rate: 11x 0…30L/h

Level

3x 1…22cm Ÿ 2x 1…29cm Experiments:

Production of biodiesel from vegetable oil

influence of dwell time

influence of temperature

Chemical transesterification

Phase separation in the gravity field

Distillation

Liquid-liquid extraction

Approach of a continuous process consisting of several basic operations

Requirements

Mains Power 220 – 240V @ 50Hz, 1Ph & 400 – 440V @ 50Hz, 3Ph

91-9829132777

91-9829132777