Hand Water Pump

Order Code: 32506

Category: Other Trainers

Hand pumps are manually operated pumps; they use human power and mechanical advantage to move fluids or airfrom one place to another. They are widely used in every country in the world for a variety of industrial, marine, irrigation and leisure activ...

SPECIFICATION

Hand pumps are manually operated pumps; they use human power and mechanical advantage to move fluids or airfrom one place to another. They are widely used in every country in the world for a variety of industrial, marine, irrigation and leisure activities. There are many different types of hand pump available, mainly operating on a piston, diaphragm or rotary vane principle with a check valve on the entry and exit ports to the chamber operating in opposing directions. Most hand pumps are either piston pumps or plunger pumps, and are positive displacement. Hand pumps are commonly used in developing countries for both community supply and self-supply of water and can be installed on boreholes or hand-dug wells. Modern hand-operated community pumps are considered the most sustainable low-cost option for safe water supply in resource-poor settings, often in rural areas in developing countries. A hand pump opens access to deeper groundwater that is often not polluted and also improves the safety of a well by protecting the water source from contaminated buckets. Pumps such as the Afridev pump are designed to be cheap to build and install, and easy to maintain with simple parts. However, scarcity of spare parts for these type of pumps in some regions of Africa has diminished their utility for these areas.

Type of Hand Pumps Suction and lift hand pumps

Suction and lift are important considerations when pumping fluids. Suction is the vertical distance between the fluid to be pumped and the centre of the pump, while lift is the vertical distance between the pump and the delivery point. The depth from which a hand pump will suck is limited by atmospheric pressure to an operating depth of less than 7 meters. The height to which a hand pump will lift is governed by the ability of the pump and the operator to lift the weight in the delivery pipe. Thus the same pump and operator will be able to achieve a greater lift with a smaller diameter pipe than they could with a larger diameter pipe. In addition to their use in drawing water from shallow groundwater sources for water supplies, another version of the hand-powered suction pump, with low lift and high delivery, was developed in the later 19th century for use as a ship's bilge pump (for smaller coastal vessels) and as a building site contractor's pump. It was known as a deluge pump.

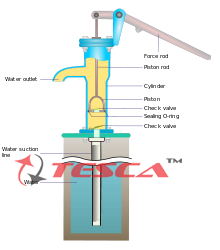

Force Pump

Where it is necessary to raise water to a height above that to which a suction or lift pump will operate effectively (about 7 metres), or to raise the pressure so that it will exit a nozzle with a strong force, such as through a fire hose, a force pump may be used. As with a suction pump, in its manual form it relies on an operator to pump a handle. The difference is however that after the water is sucked through the lower valve (as a result of raising the piston that is attached to the handle), its means of exit is via a pipe or nozzle in the side of the main cylinder. The water, once it has been drawn up above the lower valve and trapped there, is forced out the exit when the piston or plunger is pushed down again on the next stroke.

Siphon

A siphon (or syphon) at its simplest is a bent tube, with one end placed in the water to be moved, and the other end into the vessel to receive the water. The receiving vessel must be at a lower level than the supplying vessel.[9] Water will always try to find its lowest level. Using this principle, very simple pumps with plastic or rubber bulb with flap valve at each end are used for emptying fuel or water cans into tanks. Once the bulb is full, the fluid will flow without further effort from the higher to the lower container. Many hand pumps will allow the passage of fluid through them in the direction of flow and diaphragm pumps are particularly good at this. Thus where the levels are correct large volumes of liquid such as swimming pools can be emptied with very little effort and no expensive energy use.

Chain pump

A chain pump is made of an endless chain carrying a series of discs that descend into the water, and then ascend inside a tube, carrying with them a large quantity of water. They are a simply made, old hand-powered pumping technology.

Direct action

Direct action hand pumps have a pumping rod that is moved up and down, directly by the user, discharging water. Direct action hand pumps are easy to install and maintain but are limited to the maximum column of water a person can physically lift of up to 15 m.

Deep wells

Deep well hand pumps are used for high lifts of more than 15 m. The weight of the column of water is too great to be lifted directly and some form of mechanical advantage system such as a lever or flywheel is used. High lift pumps need to be stronger and sturdier to cope with the extra stresses. The installation, maintenance and repair of deep well hand pumps is more complicated than with other hand pumps. A deep well hand pump theoretically has no limit to which it can extract water. In practice, the depth is limited by the physical power a human being can exert in lifting the column of water, which is around 30 m

Diaphragm

Diaphragm pumps have the advantage that they pump relatively lightly due to the lack of pulling rods and are corrosion resistant. Their disadvantage is that they need a specific length of tubing and high quality rubber diaphragms, which are costly and are relatively inefficient due to the extra work needed to deform the diaphragm. Rubber diaphragms will eventually leak and need to be replaced. Because this is usually complicated and costly, diaphragm pumps operating in poor rural areas are often abandoned once the diaphragm wears out.

Progressive cavity

Progressive cavity pumps consist of a single helix rotor inserted into a double helix stator. As the rotor is turned, the voids in the stator are screwed upwards along the axis of rotation. Progressive cavity pumps can have complicated gearing mechanisms and are difficult for local pump technicians to maintain and repair. A rope and washer pump is a type of progressive cavity hand pump.

Range of lift

The range of lift of different types of hand pumps is given below:

Type Range

Suction pumps 0 – 7 meters

Low lift pumps 0 – 15 meters Direct action pumps 0 – 15 meters Intermediate lift pumps 0 – 25 meters

High lift pumps 0 – 45 meters, or more

Requirements

Water Source & Water Flushing system

91-9829132777

91-9829132777